Fixture design for arc welding

Would you like to increase the utilisation of your machines and produce welded assemblies in small lot sizes cost-effectively and with the same high quality? Then you should produce fixtures from sheet metal and laser-cut tubes in the future. It's easier and cheaper than you think.

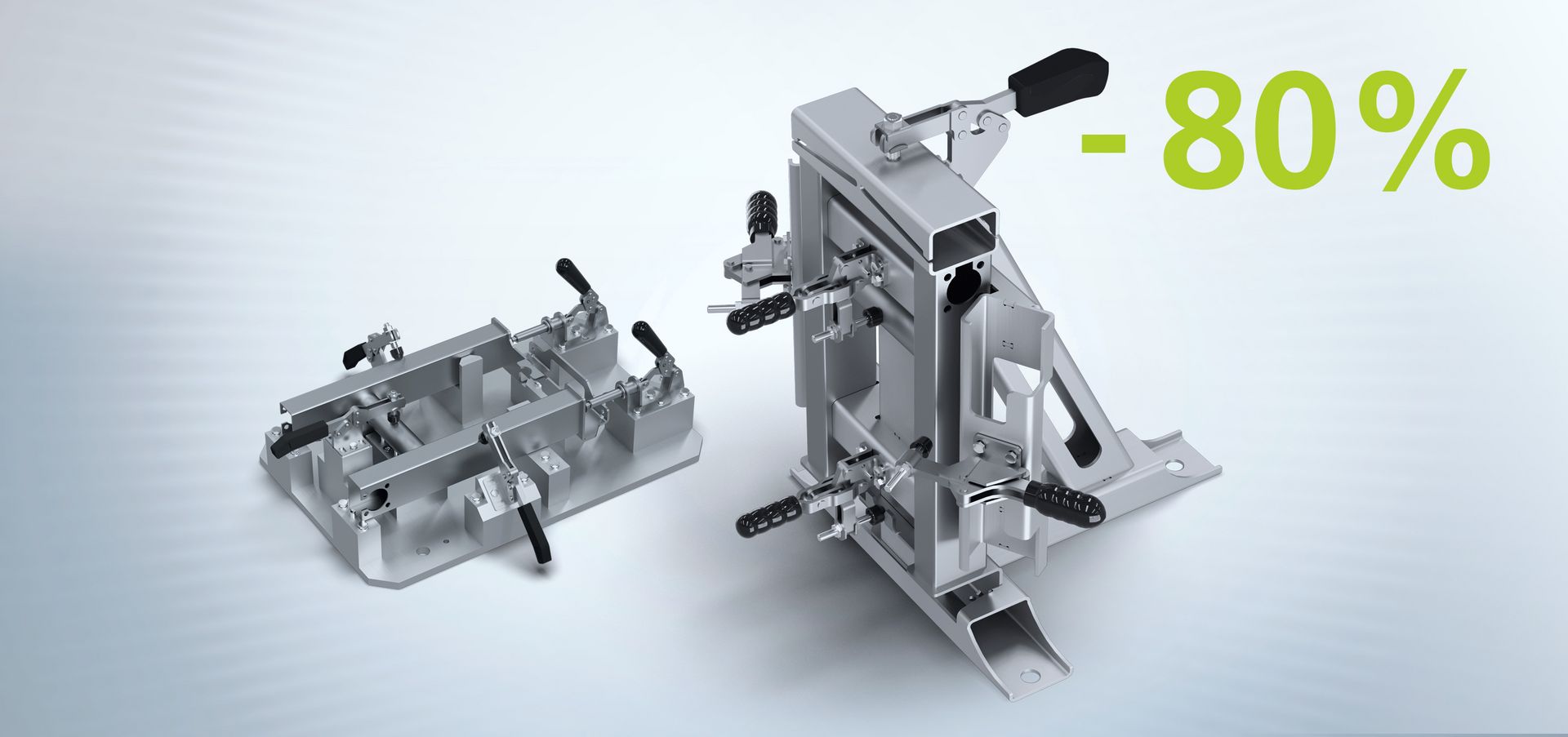

Example: optimised fixture made of tubes for arc welding

The numerous milled parts in the conventional fixture are both time-consuming and cost-intensive. The costs of chipping manufacture are high and fits for pins and threads are necessary. The assembly must be welded when it is lying down. A tube plug-in design replaces the entire milling block. Its advantages: fewer parts, less effort. The vertical design of the fixture also makes it easily accessible for manual as well as automated arc welding, e.g. on a TruArc Weld 1000.

1. Sawing

... raw materials, various semi-finished products and dimensions.

2. Milling

... all surfaces which are to be bolted or joined.

3. Drilling

... precision fits, through holes and threads.

4. Laser tube cutting

... parts including all inner geometries and joining aids in pin form.

5. Assembling

... and welding the two single parts.

6. -80% in costs

... with flexible tube design.