Benefit from direct and homogenous heat treatment of large target areas, as well as from a high tolerance to back-reflections. Thanks to the high irradiance of over 100 W/cm², the TruHeat VCSEL systems can achieve high process speeds.

Industrial TruHeat VCSEL systems

Beam sources based on VCSEL arrays are able to heat large surfaces with directed wavelength-selective infrared radiation. The TruHeat VCSEL systems are used in numerous industrial heating processes. Due to direct irradiation of the treatment surface, significant cost benefits can be achieved compared to conventional laser systems, without expensive optics or scanner systems. The unique thing about the systems is that, in addition to the precise control and fast switch-over of the infrared output, the spatial heating profile can also be programmed as needed through independent control of small segments of the laser modules. The heating patterns can even change dynamically during operation. This enables unparalleled process flexibility.

Benefit from a scalable output power in the kW range.

Achieve a high process speed with irradiance of 100 W/cm².

Individual emission zones of the VCSEL beam source can be controlled independently of one another.

The robust and compact laser modules can be integrated easily into industrial systems and production processes.

E-mobility: drying battery foils

The active material on the electrode foil must be dried after the recoating process. Industrial VCSEL heating systems can perform this step, because beam sources based on VCSEL arrays are able to heat large surfaces with directed wavelength-selective infrared radiation.

E-mobility: sealing pouch cells

Using TruHeat VCSEL systems to seal pouch cells increases the quality of the sealing results. In addition, VCSEL heating systems reduce process time and the process is up to three times faster in comparison.

Local softening of body steel in the automotive industry

TruHeat VCSEL systems make it quick and easy to selectively soften high-tensile steel parts. This has many benefits, particularly in automotive production.

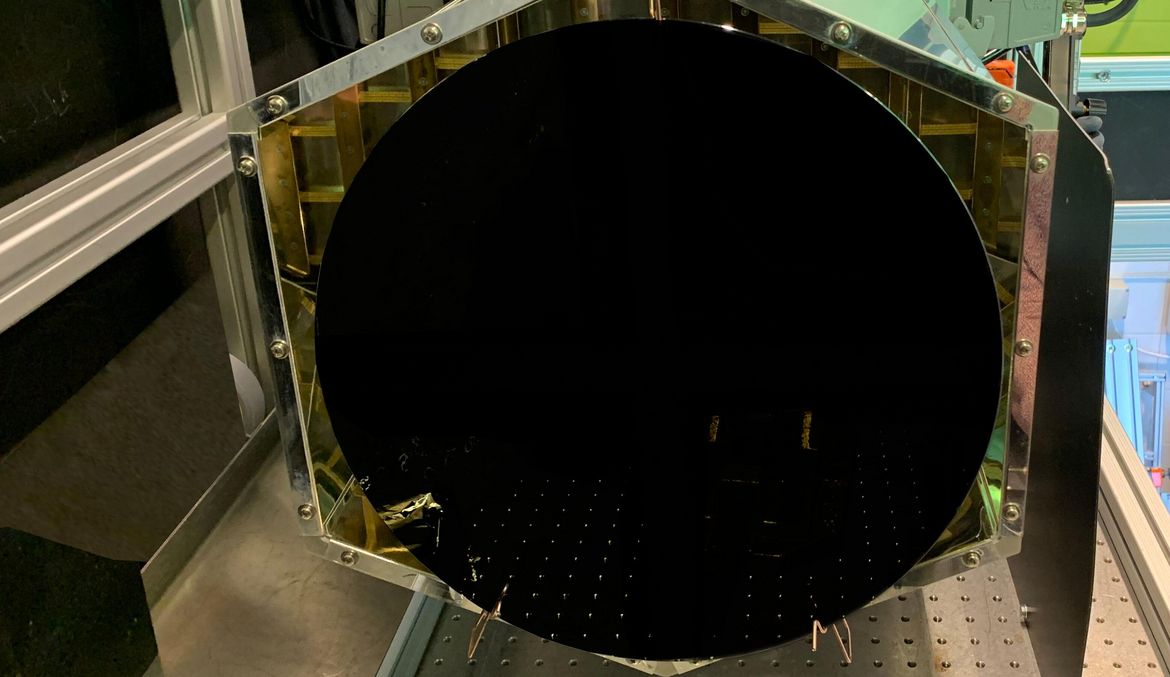

Wafer heating

VCSEL lasers can be used in the semiconductor industry for heating the wafers for Rapid Thermal Processing (RTP). TruHeat VCSEL systems make it possible to heat wafers quickly and uniformly as the individual heat zones can be superbly controlled. Temperature increases of several hundred degrees Celsius can be achieved per second.

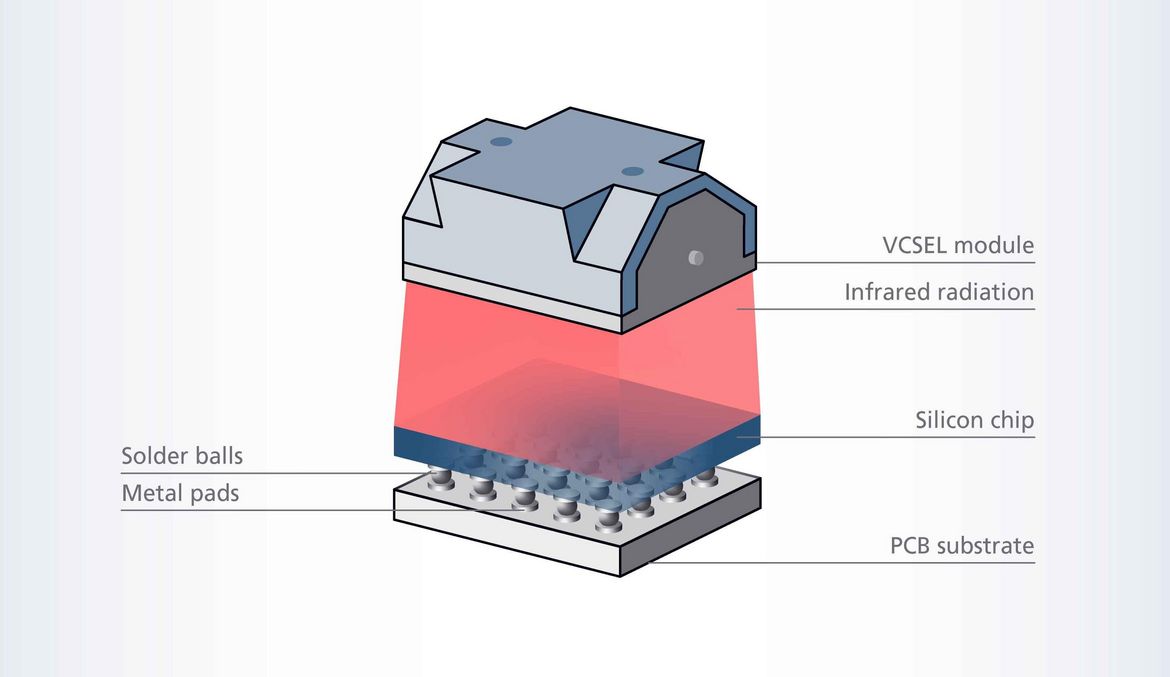

Semiconductor production: Laser Assisted Bonding (LAB)

Using solder balls, a flip chip is positioned as a connecting element on a printed circuit board in Laser Assisted Bonding (LAB). A TruHeat VCSEL system irradiates the chip from above and the laser energy is transferred by a silicon chip in order to melt the solder balls between the chip and the printed circuit board. Compared to other solutions, VCSEL-based systems provide larger heating surfaces with higher output options.

Semiconductor production: Laser Assisted Soldering (LAS)

In Laser Assisted Soldering (LAS), the solder balls are connected directly with the soldering pads on the printed circuit board using VCSEL infrared heat treatment. This is particularly interesting if smaller solder ball and pitches are used. The VCSEL heating system technology offers highly precise heating and top solder joint quality. The LAS process also helps to increase the service life of printed circuit boards.

Additive manufacturing with metals (preheating)

3D-printed high-volume components made from metal have thermal gradients that often have a negative effect on the sintered parts. With VCSEL-based heating systems, stress can be minimised from above. This is because the heat from the laser significantly reduces thermal stress and distortion on the printed part. This improves the mechanical properties of the component.

Fast joining of large plastic parts in furniture board production

Benefit from quick welding of large plastic parts thanks to high irradiance in the homogenously irradiated heating zone. Integration is very easy due to the small dimensions of the module.

Photovoltaics: laser-powered co-firing process, ultrafast regeneration und light soaking process

TruHeat VCSEL systems open up numerous benefits in solar cell production. For example, during the process of selective burning-in of the contacts on the solar cell. There are benefits for regeneration processes as well: the intensive irradiation of the cell decreases defects and removes energy barriers, therefore increasing efficiency.

|

TruHeat VCSEL 3010 (2.4 kW)

Compare product

|

TruHeat VCSEL 3010 (9.6 kW)

Compare product

|

TruHeat VCSEL 3010 (19.2 kW)

Compare product

|

TruHeat VCSEL 3012

Compare product

|

|

|---|---|---|---|---|

| Laser parameters | ||||

| Wavelength | 980 nm | 980 nm | 980 nm | 980 nm |

| Laser power | 2.4 kW | 9.6 kW | 19.2 kW | 6 kW |

| Beam angle | Typically with 10° (at 95% power) | Typically with 10° (at 95% power) | Typically with 10° (at 95% power) | Typically with 10° (at 95% power) |

| Number of zones | 12 pieces | 48 pieces | 96 pieces | 30 pieces |

| Emission range | 40 x 52 mm2 | 40 x 208 mm2 | 417.5 x 38 mm2 | 521.6 x 25.3 mm2 |

| Irradiance | typisch 115 W/cm2 | typisch 115 W/cm2 | typisch 115 W/cm2 | typisch 115 W/cm2 |

| Laser class | 4 | 4 | 4 | 4 |

| Optics | ||||

| Optical element | Optionally with focusing or scattering optics | Optionally with focusing or scattering optics | Optionally with focusing or scattering optics | Optionally with focusing or scattering optics |

| Protective glass |

Double safety glass, anti-reflective coated |

Double safety glass, anti-reflective coated |

Double safety glass, anti-reflective coated |

Double safety glass, anti-reflective coated |

| Size | ||||

| Width dimension | 87 mm | 87 mm | 112.7 mm | 133.5 mm |

| Height dimension | 48 mm | 48 mm | 113 mm | 87 mm |

| Depth dimension | 108 mm | 264 mm | 563 mm | 652 mm |

| Driver unit | ||||

| Number of driver units | 1 pieces | 4 pieces | 1 pieces | 1 pieces |

| Laser control | Typically with 10 ms time constant; individual control of laser emission zones; integrated laser monitoring | Typically with 10 ms time constant; individual control of laser emission zones; integrated laser monitoring | Typically with 10 ms time constant; individual control of laser emission zones; integrated laser monitoring | Typically with 10 ms time constant; individual control of laser emission zones; integrated laser monitoring |

| Machine interface | Ethernet-based (EtherCAT® protocol) | Ethernet-based (EtherCAT® protocol) | Ethernet-based (EtherCAT® protocol) | Ethernet-based (EtherCAT® protocol) |

| Power supply | 400V (±10%) between 3 phases, 47-63 Hz | 400V (±10%) between 3 phases, 47-63 Hz | 400V (±10%) between 3 phases, 47-63 Hz | 400V (±10%) between 3 phases, 47-63 Hz |

| Installation | ||||

| Ambient temperature | 5 - 40 °C | 5 - 40 °C | 5 - 40 °C | 5 - 40 °C |

| Humidity (max.) | Non-condensing for cooling water temperature of 20 °C | Non-condensing for cooling water temperature of 20 °C | Non-condensing for cooling water temperature of 20 °C | Non-condensing for cooling water temperature of 20 °C |

| Chiller | Cooling device with water-water or water-air heat exchanger required | Cooling device with water-water or water-air heat exchanger required | Cooling device with water-water or water-air heat exchanger required | Cooling device with water-water or water-air heat exchanger required |

|

TruHeat VCSEL 3010 (2.4 kW)

|

TruHeat VCSEL 3010 (9.6 kW)

|

TruHeat VCSEL 3010 (19.2 kW)

|

TruHeat VCSEL 3012

|

|

|---|---|---|---|---|

| Laser parameters | ||||

| Wavelength | 980 nm | 980 nm | 980 nm | 980 nm |

| Laser power | 2.4 kW | 9.6 kW | 19.2 kW | 6 kW |

| Beam angle | Typically with 10° (at 95% power) | Typically with 10° (at 95% power) | Typically with 10° (at 95% power) | Typically with 10° (at 95% power) |

| Number of zones | 12 pieces | 48 pieces | 96 pieces | 30 pieces |

| Emission range | 40 x 52 mm2 | 40 x 208 mm2 | 417.5 x 38 mm2 | 521.6 x 25.3 mm2 |

| Irradiance | typisch 115 W/cm2 | typisch 115 W/cm2 | typisch 115 W/cm2 | typisch 115 W/cm2 |

| Laser class | 4 | 4 | 4 | 4 |

| Optics | ||||

| Optical element | Optionally with focusing or scattering optics | Optionally with focusing or scattering optics | Optionally with focusing or scattering optics | Optionally with focusing or scattering optics |

| Protective glass |

Double safety glass, anti-reflective coated |

Double safety glass, anti-reflective coated |

Double safety glass, anti-reflective coated |

Double safety glass, anti-reflective coated |

| Size | ||||

| Width dimension | 87 mm | 87 mm | 112.7 mm | 133.5 mm |

| Height dimension | 48 mm | 48 mm | 113 mm | 87 mm |

| Depth dimension | 108 mm | 264 mm | 563 mm | 652 mm |

| Driver unit | ||||

| Number of driver units | 1 pieces | 4 pieces | 1 pieces | 1 pieces |

| Laser control | Typically with 10 ms time constant; individual control of laser emission zones; integrated laser monitoring | Typically with 10 ms time constant; individual control of laser emission zones; integrated laser monitoring | Typically with 10 ms time constant; individual control of laser emission zones; integrated laser monitoring | Typically with 10 ms time constant; individual control of laser emission zones; integrated laser monitoring |

| Machine interface | Ethernet-based (EtherCAT® protocol) | Ethernet-based (EtherCAT® protocol) | Ethernet-based (EtherCAT® protocol) | Ethernet-based (EtherCAT® protocol) |

| Power supply | 400V (±10%) between 3 phases, 47-63 Hz | 400V (±10%) between 3 phases, 47-63 Hz | 400V (±10%) between 3 phases, 47-63 Hz | 400V (±10%) between 3 phases, 47-63 Hz |

| Installation | ||||

| Ambient temperature | 5 - 40 °C | 5 - 40 °C | 5 - 40 °C | 5 - 40 °C |

| Humidity (max.) | Non-condensing for cooling water temperature of 20 °C | Non-condensing for cooling water temperature of 20 °C | Non-condensing for cooling water temperature of 20 °C | Non-condensing for cooling water temperature of 20 °C |

| Chiller | Cooling device with water-water or water-air heat exchanger required | Cooling device with water-water or water-air heat exchanger required | Cooling device with water-water or water-air heat exchanger required | Cooling device with water-water or water-air heat exchanger required |

The technical data of all product versions as a download.

TruHeat VCSEL Series 3000

The standard modules of the TruHeat VCSEL Series 3000 are available in 2.4 kW, 4.8 kW, 9.6 kW and 19.2 kW versions. The standard modules are used for directional, large-area heating applications. The beam is directed straight at the respective application area without the additional use of optics or a scanner system.

TruHeat VCSEL 3012

The TruHeat VCSEL 3012 system has a relatively low irradiance with a large width. This is why it is especially suitable for drying battery foils. Several modules can be arranged one after the other to create a longer drying path.

Specialised solutions

The VCSEL heating systems are flexible and can be easily adapted to customised requirements. Depending on the customer application, the correct configuration of VCSEL heating system is determined together with the customer.

The image shows a compact laser module with 32 VCSEL arrays and focusing optics for use in the 3D printing of plastics or the marking of packaging material. Each VCSEL array can be controlled individually, with an output power of 2 W.

Control software for TruHeat VCSEL systems

Basic Driver Control Software

The basic version of the control software offers the function of manually controlling the laser channels of the TruHeat VCSEL system and of setting the power.

Advanced Driver Control Software

The extended control software version is based on the basic version and offers additional functions such as temperature control or pulsing. In addition, time and performance profiles can be created. These can be used to vary the power of the TruHeat VCSEL system during the processing time.

The heat density of TruHeat VCSEL systems can be influenced with additional lenses. The irradiance of VCSEL heating modules can be increased with positive lenses. The use of negative lenses decreases the irradiance of the modules.

The Air Knife can be used to keep spatter and steam away from the protective glass of the laser system. It creates a protective airflow in front of the laser.

Mounting brackets simplify the technical assembly of a TruHeat VCSEL system.

A TruHeat VCSEL system with less tightly packed emitters and a defocusing lens can be used for applications requiring less irradiance.

This product range and information may vary depending on the country. Subject to changes to technology, equipment, price and range of accessories. Please get in touch with your local contact person to find out whether the product is available in your country.