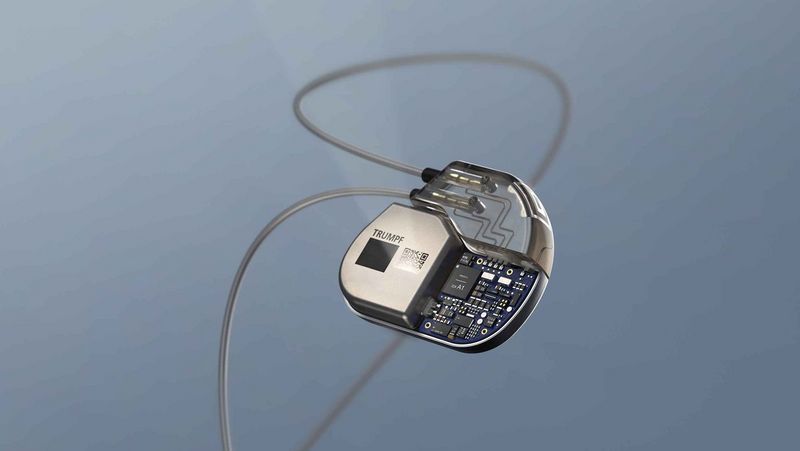

Over the last few decades, laser technology hasn't just changed how medical professionals treat their patients, it has revolutionised the way companies manufacture medical devices. Implantable pacemakers, balloon catheters or stents - life-saving medical products would be inconceivable without modern laser technology. Laser systems enable manufacturers of medical devices and medical components to process even the smallest components precisely, flexibly and in sterile conditions. They also enable the use of advanced and biocompatible materials. Interventions are thus easier for the patient to tolerate, improving treatment results.

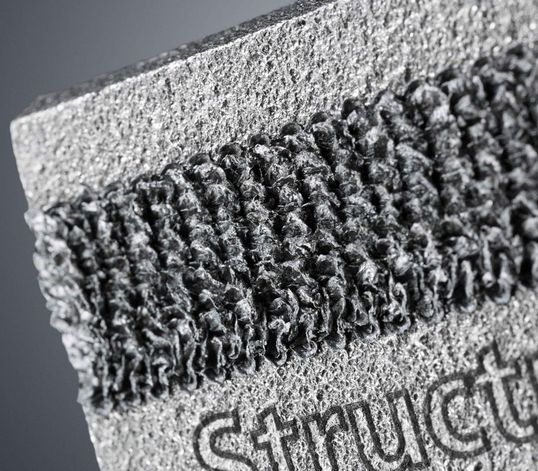

Of course, lasers also meet the high demands that the highly regulated industry places on the development of medical devices. They create products of consistently flawless quality. Lasers can be used in a variety of ways: for welding, cutting, marking and structuring, or for removing coatings. You too can rely on laser processing and thus on maximum process reliability, accuracy and quality.