Fully automated processes from programming to cutting and sorting – for maximum efficiency and minimal processing costs!

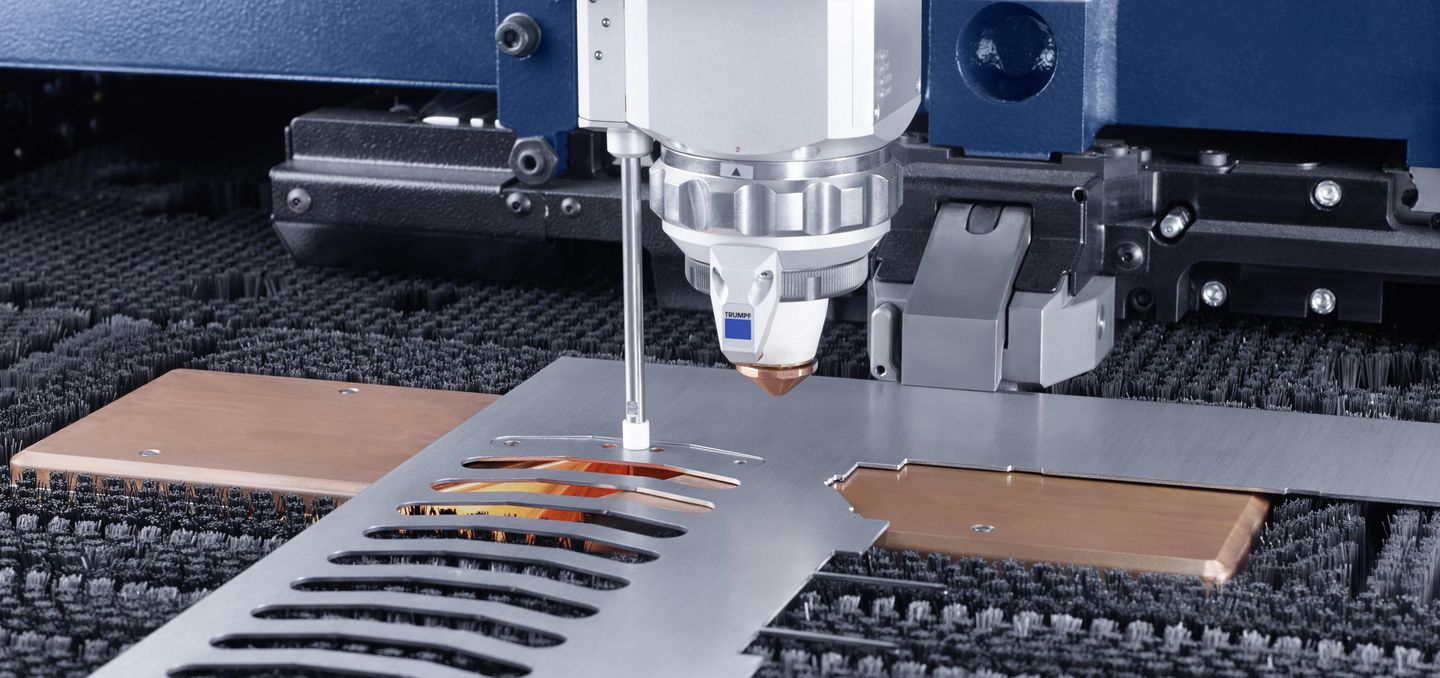

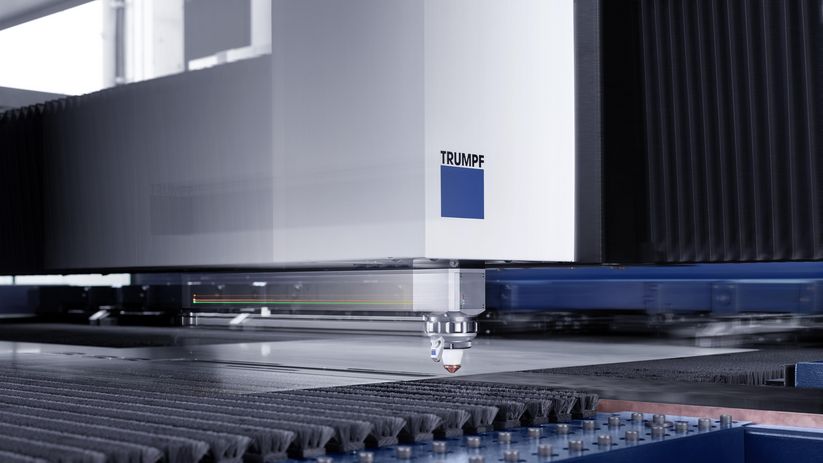

The TruLaser Center 7030 integrates all laser cutting processes into a single machine for the first time. We scrutinised and redesigned all components and integrated them in a single machine. As a result, you get the optimal profitability out of your laser machining process.

Vision Equipment provides an unobstructed view of the machine interior.

The SmartGate prevents the tilting and unwanted welding of parts.

Additional axes, SmartGate, brush tables and SmartLift ensure groundbreaking productivity and total reliability

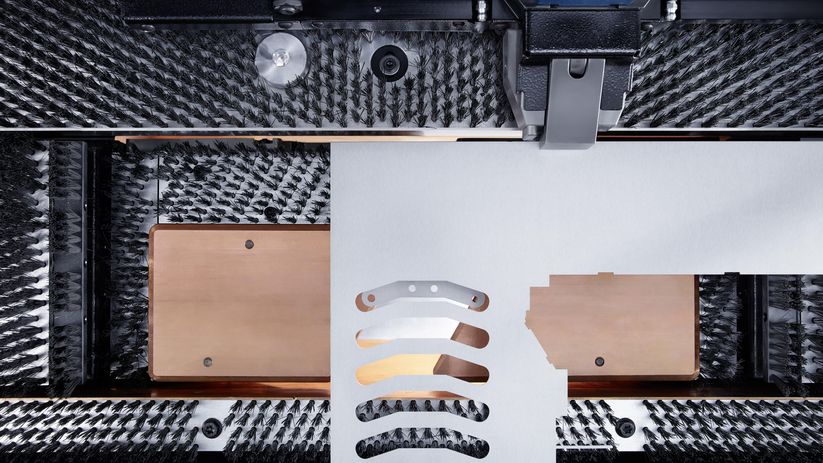

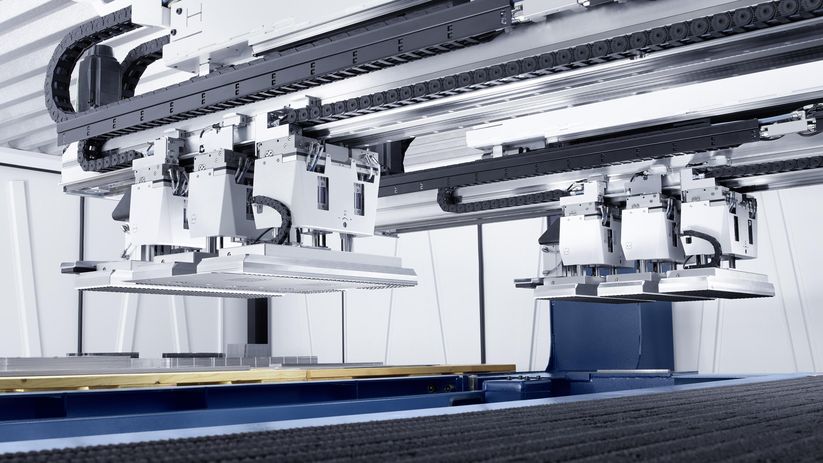

The SortMaster Speed removes and stacks large and also extremely delicate components at lightning speed.

TruTops Boost automatically generates a suggestion for the cutting, removal, sorting and depositing of parts.

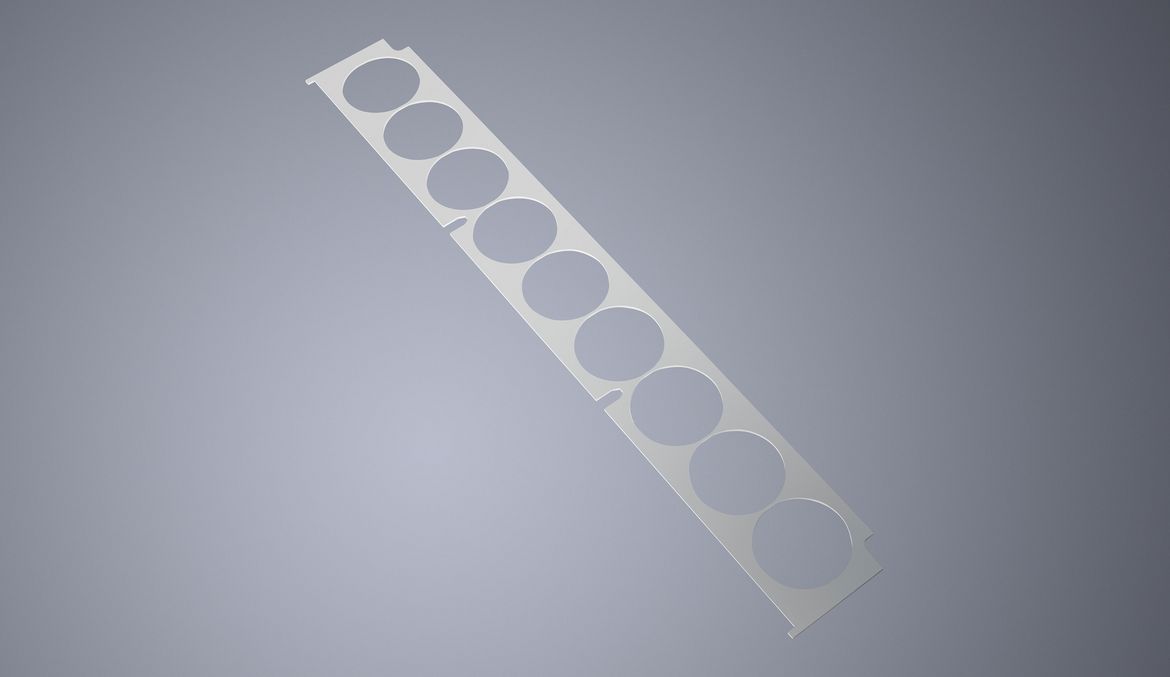

Thin mild steel part

Your TruLaser Center 7030 fiber cuts extremely quickly, particularly in thin sheet.

Cutting of all common materials

The construction of the TruFiber enables the processing of non-ferrous metals with nitrogen – without worrying about back-reflections.

Automated part removal

The versatile unloading system SortMaster Speed removes and stacks large and highly delicate components extremely fast. Even parts with a manufacturing process that is difficult to automate can be transported quickly thanks to the small suction cup.

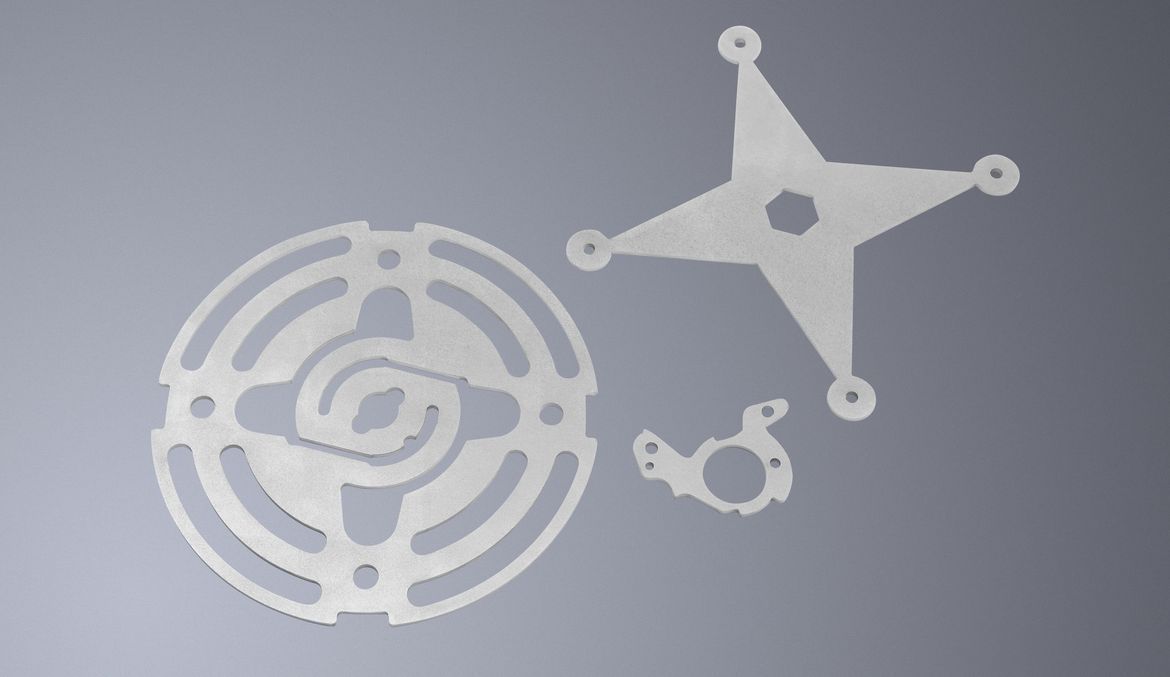

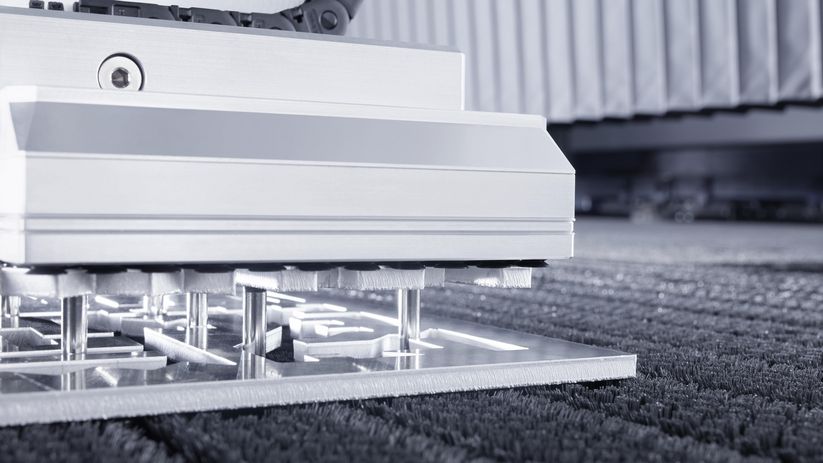

Perfected part separation

No more tilting or getting stuck: With SmartLift and SortMaster Speed, you can process and remove even complex geometries reliably and fully automatically.

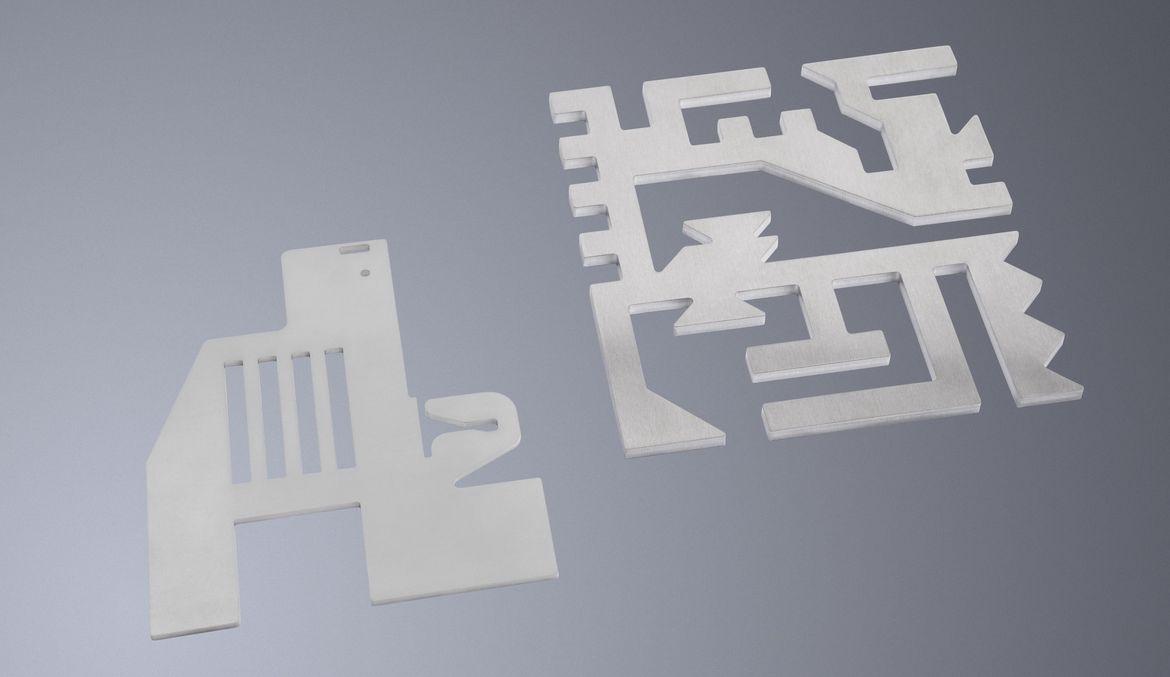

Reliable parts handling

Parts that until now could only be processed reliably using microjoints can now be cut and removed securely using the TruLaser Center 7030. This opens up entirely new possibilities for the processing of very small parts.

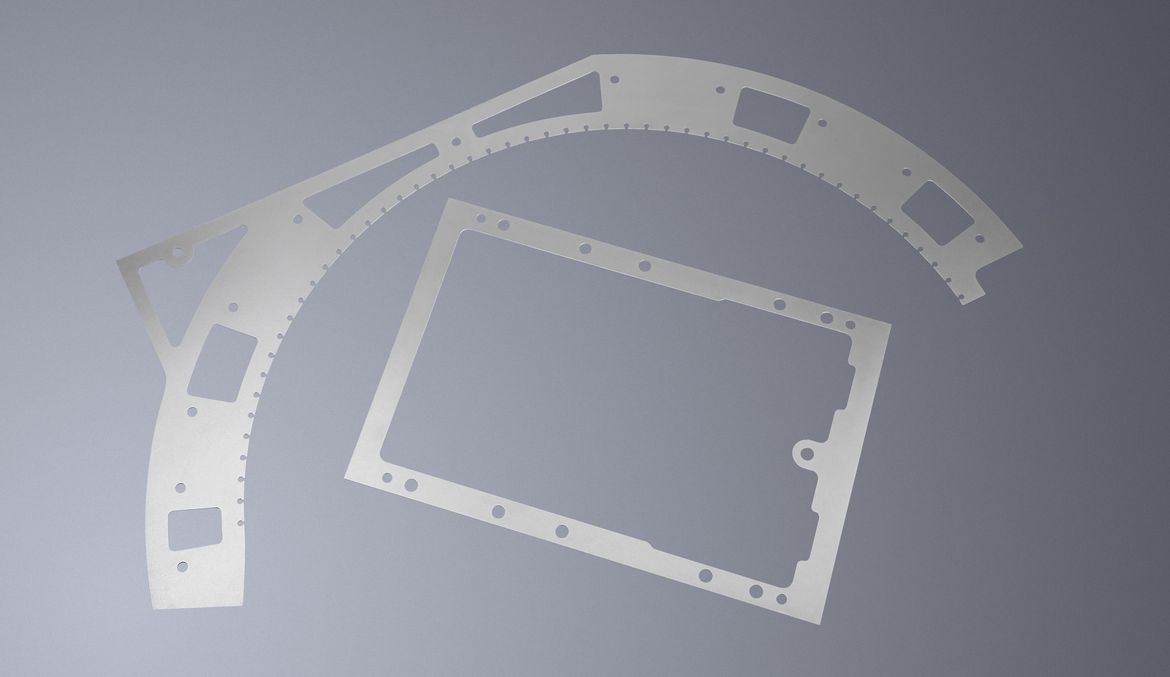

Internal reinforcement

Different geometries and sheet thicknesses can be manufactured with the TruLaser Center 7030, both with process reliability and to an excellent quality standard. This sample part has an interior reinforcement for welded housings made of steel sheet with a thickness of just 1 mm.

Stiffening plate

This 1.5 mm thick steel sheet part has a stiffening plate for cross member units and is part of the TruLaser Center 7030 clamping unit.

Locking mechanism

This sample part made of steel sheet has a thickness of 12 mm and locks the tilt mechanism of the TruLaser Center 7030.

|

TruLaser Center 7030

|

|

|---|---|

| Installation surface | |

| Length | 10135 mm |

| Width (cart extended) | 10720 mm |

| Width (cart retracted) | 6420 mm |

| Height | 3050 mm |

| Weight with all units | 38860 kg |

| Nominal working range | |

| X axis | 3000 mm |

| Y axis | 1500 mm |

| Z axis | 120 mm |

| Laser-specific data TruFiber 6001 | |

| Maximum laser power | 6000 W |

| Maximum sheet thickness, mild steel | 12.7 mm |

| Maximum sheet thickness, stainless steel | 12.7 mm |

| Maximum sheet thickness, aluminium | 6 mm |

| Maximum sheet thickness, brass | 6 mm |

| Maximum sheet thickness, copper | 6 mm |

| Laser-specific data TruFiber 12001 | |

| Maximum laser power | 12000 W |

| Maximum sheet thickness, mild steel | 12.7 mm |

| Maximum sheet thickness, stainless steel | 12.7 mm |

| Maximum sheet thickness, aluminium | 6 mm |

| Maximum sheet thickness, brass | 6 mm |

| Maximum sheet thickness, copper | 6 mm |

| Unloading automation SmartGate | |

| Maximum part size | 160 mm x 160 mm |

| Minimum part size | 30 mm x 30 mm |

| SortMaster Speed unloading automation | |

| Maximum part size | 2000 mm x 1500 mm 1 |

| Minimum part size | 90 mm x 60 mm |

Reliable or fast? The TruLaser Center 7030 resolves this classic conflict in laser processing for the very first time.

Reliable

Together with the brush tables, the SmartGate prevents the tilting and unwanted welding of parts. The intelligent support moves along with the cutting head and provides support for your parts during cutting. The ejector cylinder automatically finds the best point for every part geometry to push the part out of the scrap skeleton and remove it securely.

The pins of the SmartLift, which can be positioned flexibly, press the cut parts against the suction plate of the SortMaster Speed from below. At the same time, the suction plate secures the part from above. Fixed in this way, the part is taken out of the scrap skeleton by a synchronous lift motion. This means that even delicate parts are held securely and do not tilt in the kerf.

Quick

The movement of the sheet is superimposed by a highly dynamic additional axis on the cutting head. This means that you can cut around corners and complex contours at high speeds. This strong combination enables you to get the most out of the high feed rates of the solid-state laser.

The SmartGate removes small parts into up to eight containers within seconds. Punching slugs and scrap fall into a slag cart. Your key for maximum throughput: The removal of residual material causes minimal interruption to the cutting process – thanks to the intelligent control and sensor system of the SmartGate.

The SortMaster Speed stacks parts perfectly on up to eight pallets at lightning speed. As soon as the SortMaster Speed takes the part, the machine continues cutting. The part is taken to its deposit position parallel to production. There is minimal interruption to the machining process.

The LoadMaster Center places the unprocessed sheets on the brush table in the clamping unit. High-performance peeling technology separates the sheets reliably from the stack.

Automated

The TruTops Boost programming system automatically generates a suggestion for the cutting, removal, sorting and depositing of your parts. In doing so, it even takes physical conditions into consideration. For example, how the part can best be pushed out of the scrap skeleton to eliminate any chance of it tilting.

A sorting flap reliably separates finished parts from scrap. The SortMaster Box Linear sorting unit distributes small parts into up to eight containers parallel to production. The containers are assigned intelligently by the software program.

Self-reliant

The processing cell loads and unloads independently and indicates when the operator is needed. Because of this, the operator can plan their work at the machine better. Waiting times, manual sorting and reworking are no longer required. The Touchpoint user interface also enables an intuitive dialogue with the machine.

Through program control, the automatic nozzle changer inserts the correct nozzle. The nozzle changer is located in the machine cabinet during processing, which makes it possible to set up parallel to production.

Seamless integration of many TRUMPF machines into your own software environment is very easy. We have the right solution for every combination, whether it be integration into Oseon or a connection to monitoring and analysis tools. A connection to third-party software systems is also possible with our interfaces based on the OPC UA standard.

Are you looking for an unobstructed view of the machine interior? If so, this is where Vision Equipment comes in – with carefully positioned cameras and perfectly coordinated lighting. Smart View for machine tools allows you to follow your camera live streams in real time, giving you constant visibility into the interior of your TruLaser Center 7030.

TruTops Boost

Construct and program your laser, punching and combination punch laser machines intelligently with TruTops Boost, your all-in-one 3D solution. Numerous automated processes save you time-consuming routine processes and the joint nesting pool saves time and material. You also always have an overview of all manufacturing orders and order-based work.

Smart View for machine tools – connect your machine and reap the benefits

Smart View is now available free of charge when you purchase a new machine. Smart View automatically displays relevant operation data for your machine tools. Simply click on your dashboard to get an initial comprehensive insight into the performance of your TRUMPF machines.

Software

The software portfolio from TRUMPF optimises your entire production process – from the customer query to delivery of the finished part. TRUMPF combines the software intelligently with machines and services to create customised Industry 4.0 solutions for your Smart Factory.

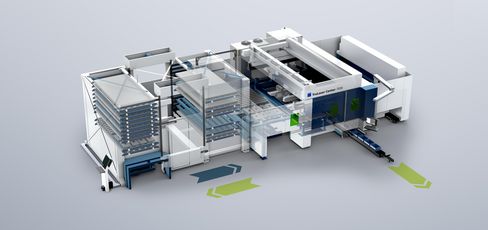

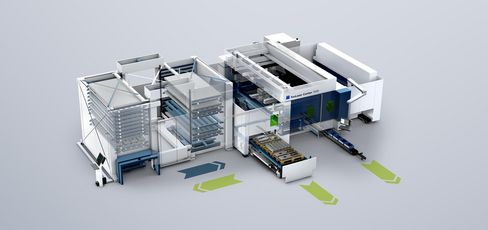

Take full advantage of the huge productivity of your machine – thanks to the TruLaser Center 7030's connection to a store, your machine is always supplied with unprocessed material and can store finished parts.

Large store, short distances

Connect your TruLaser Center 7030 to all common storage systems, such as the TruStore store from TRUMPF or large-scale storage systems from STOPA. The modular stores can always be customised and extended to fit your needs.

Side storage connection for unprocessed material and finished parts

Unprocessed material enters the machine from the side. While the stacked finished parts return into the store on pallets, small parts in boxes are removed from the front of the machine. The tandem relay gives you direct access to the next storage pallet and reduces waiting times.

Side storage connection for raw material and finished parts with flexible access to parts

The machine is supplied with raw material from the store from the side. Handle finished parts flexibly, for example you can remove them directly from the machine during the day, and place them back in the store at night. You can also remove parts directly from the unloading cart, or use a moving floor or storage palette compatible with forklift trucks – the solutions are numerous and always suit your requirements.

This product range and information may vary depending on the country. Subject to changes to technology, equipment, price and range of accessories. Please get in touch with your local contact person to find out whether the product is available in your country.

- Dimensions may vary slightly due to technical machine characteristics.

Access exclusive videos about the TruLaser Center 7030

Obtain insights into manufacturing with the TruLaser Center 7030

Would you like to see the TruLaser Center 7030 in action? TRUMPF experts provide virtual insights from the Customer Center in Ditzingen.

Watch exclusive videos now

Welcome back!

We are unlocking access to exclusive content for you!

We are currently reviewing your data...

Just one more step to gain access!

Many thanks for your interest in our exclusive content. Please open your inbox and confirm your address. Then you'll receive full access. Please check your spam folder as well.

Access not possible

Unfortunately, your registration for our exclusive content was not successful. Please contact us at info@trumpf.com or use the contact form.

Unfortunately, an error has occurred. Please try again later.