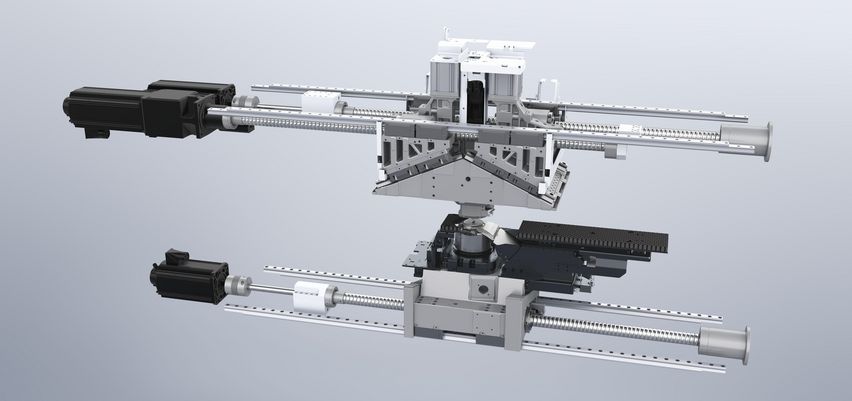

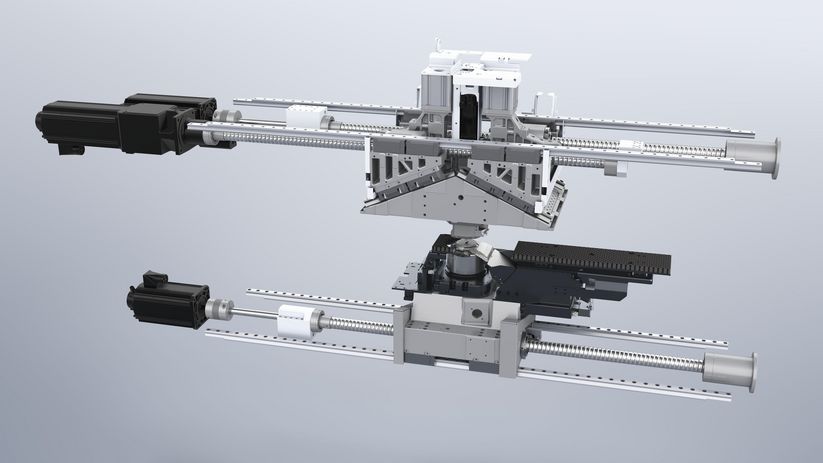

Compact, dynamic, and efficient – the patented Delta Drive takes away the need for the sheet and support table to move in the Y axis because it enables the punching head to "fly", i.e. to move back and forth, for the very first time. In addition, the electric punch drive saves significantly more energy compared to hydraulically driven punching machines.

Productive universal machine for punching parts of the highest quality

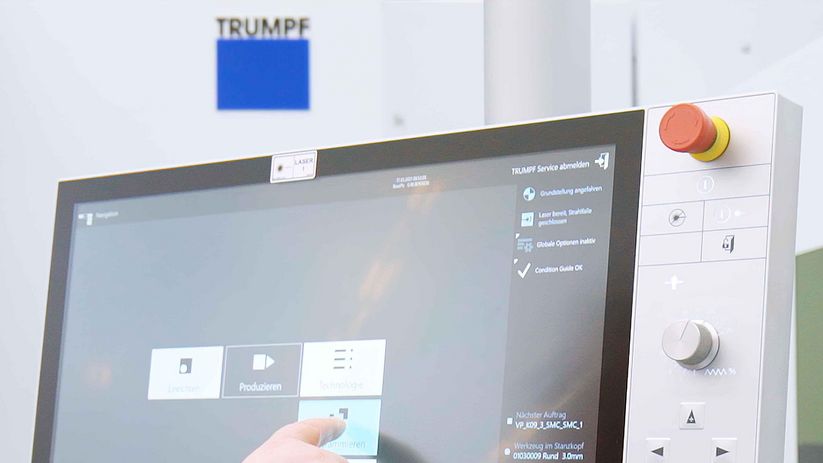

For anyone who would like to punch efficiently and yet economically: the compact TruPunch 3000 is your complete solution for versatile part processing. It achieves outstanding part quality thanks to the descending die and is easy to operate with the touchpoint HMI.

You can punch, form, tap, emboss, mark, engrave and deburr with a TruPunch machine.

Scratch-free punching thanks to the descending die.

Removal and sorting solutions for small to large parts. The SheetMaster Compact loads and unloads, the SortMaster Compact sorts finished parts.

With the dynamic Delta Drive you need less than 30 m² installation surface and significantly less energy than with hydraulic drives.

At TRUMPF you get top quality punching tools for creating threads or bends in your parts, for example.

Fewer operating steps, easy to learn – the touchpoint HMI makes it much easier to work with the machine.

Electronic component

Produce with flexibility using tools for every application, such as tabs, cups and roller offsetting. For this component, the following tools were used: stepping tool, bracket tool, cup tool rectangular and round, offsetting roller tool and pinching roller tool.

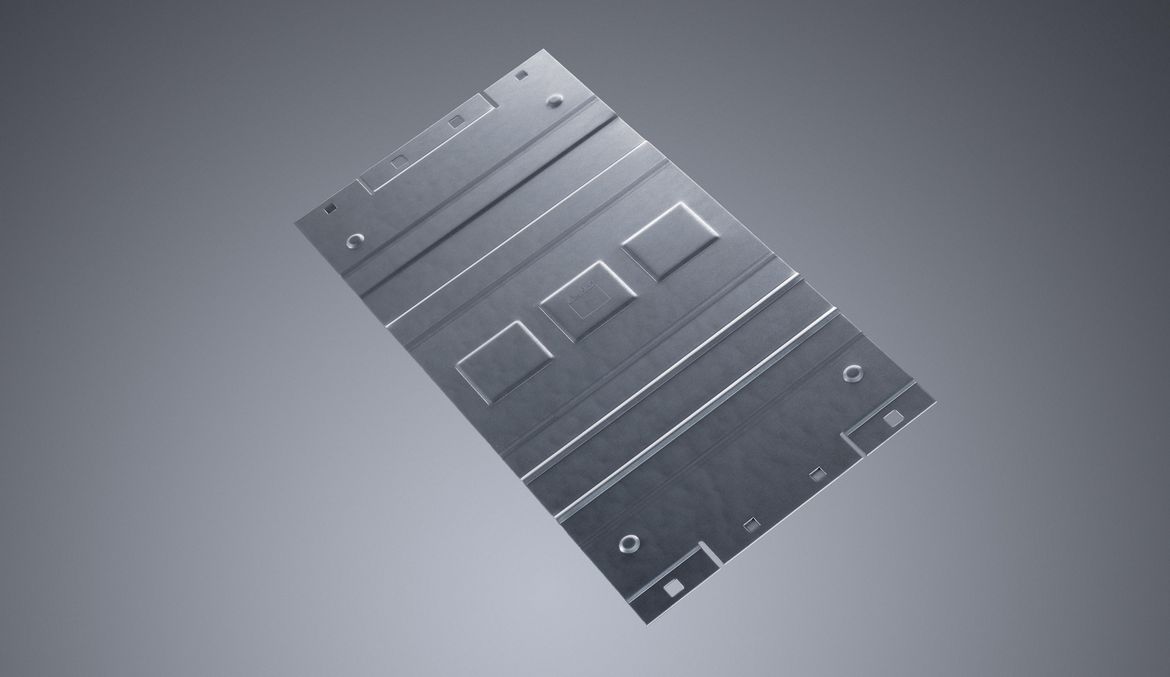

Workpiece

With the largest tool range in the world, the machine offers the highest level of processing flexibility. For this workpiece, the following tools were used: roller beading tool, MultiCut tool, cup tool and roller offsetting tool.

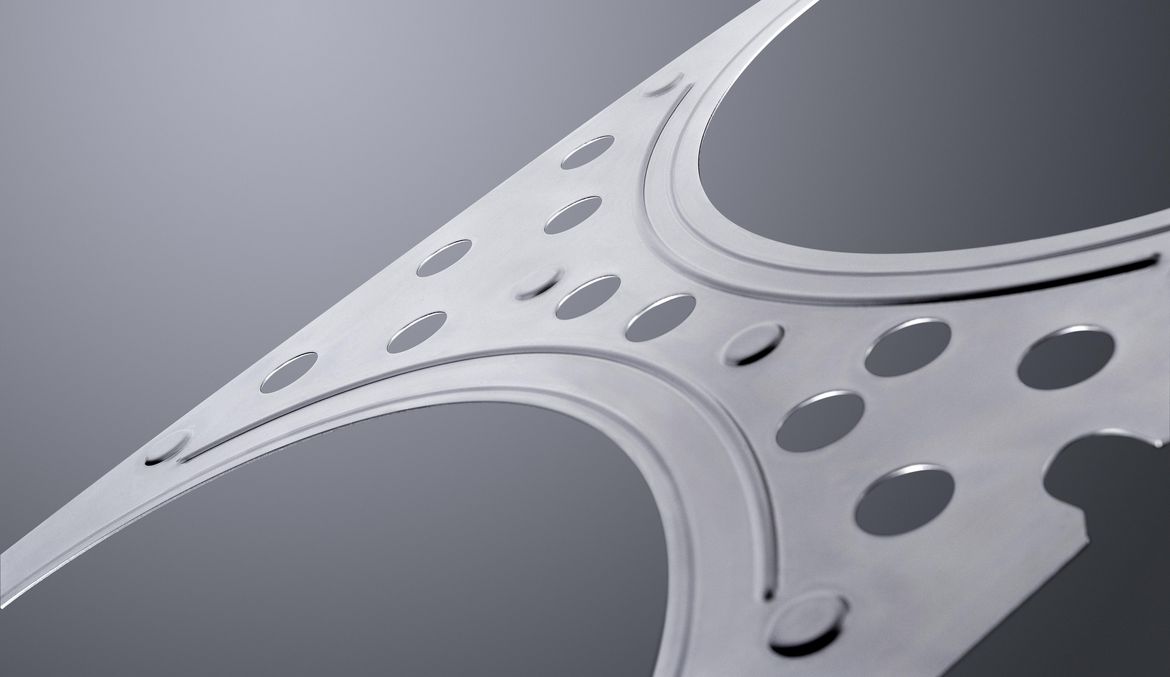

Workpiece

Using the MultiBend tool, you can produce 90° bends in a variety of lengths. For this workpiece, the following tools were used amongst others: MultiBend, extrusion tool, tapping tool, cup tool and bridge tool.

Embossing of numbers and letters

Using the embossing tool you can mark parts with flexibility, including the widest range of letters and numbers.

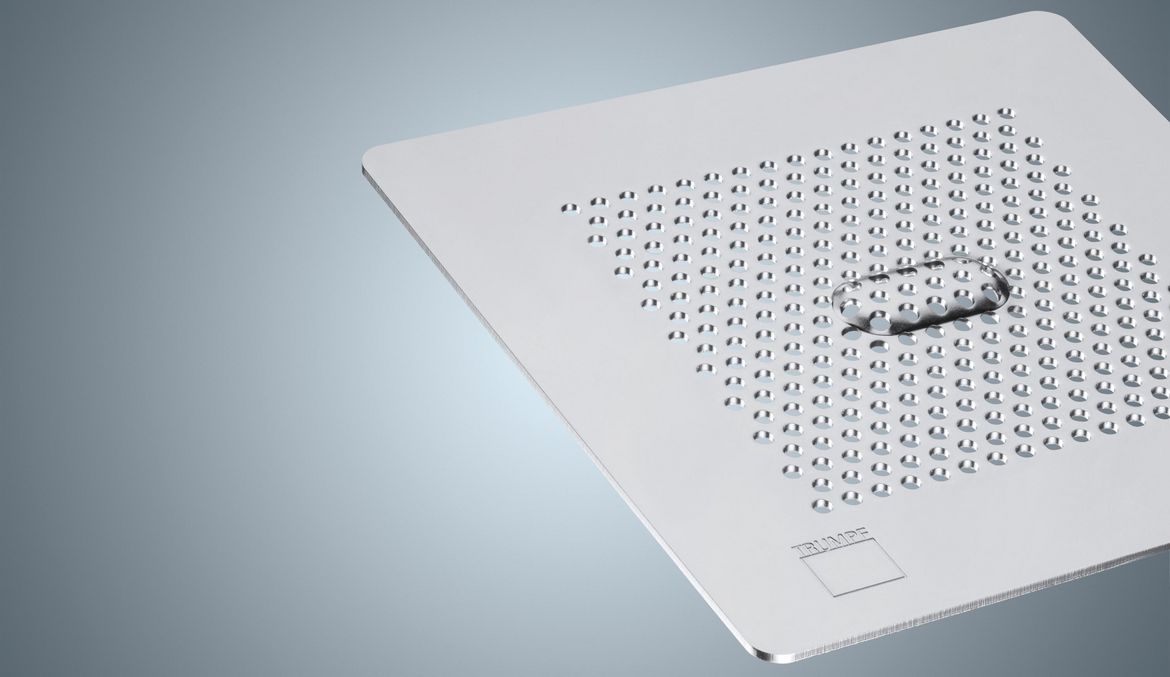

Integrated flattening

The "integrated flattening" machine function and the corresponding tool make it possible to even out surface irregularities during the punching process itself – without any post-processing.

|

TruPunch 3000 medium format

|

TruPunch 3000 large format

|

|

|---|---|---|

| Dimensions | ||

| Width | 6282 mm | 7644 mm |

| Depth | 6548 mm | 7666 mm |

| Height | 2200 mm | 2200 mm |

| Maximum stroke rate | ||

| Punching (E = 1 mm) | 800 1/min | 690 1/min |

| Marking | 1000 1/min | 1000 1/min |

| Working range | ||

| Punching mode, X axis | 2500 mm | 3000 mm |

| Punching mode, Y axis | 1250 mm | 1550 mm |

| Maximum sheet thickness | 6.4 mm | 6.4 mm |

| Maximum workpiece weight | 150 kg | 230 kg |

| Maximum punching force | 180 kN | 180 kN |

| Tools | ||

| MultiTool changing time | 0.5 s | 0.5 s |

| Number of tools/clamps | 18 pieces / 2 pieces | 21 pieces / 3 pieces |

| Part removal | ||

| Maximum part size, part removal flap, punching | 400 mm x 600 mm | 400 mm x 600 mm |

| Maximum part size – fixed punching chute (with moving table) | 180 mm x 180 mm | 180 mm x 180 mm |

| Consumption values | ||

| Average power input of active auto-shutdown | 0.5 kW | 0.5 kW |

| Average power input in production | 3.3 kW | 3.3 kW |

The technical data of all product versions as a download.

With the TruPunch 3000, you are not only manufacturing in a particularly flexible way, but also to the highest quality. Innovative functions guarantee the best processing results.

Quality

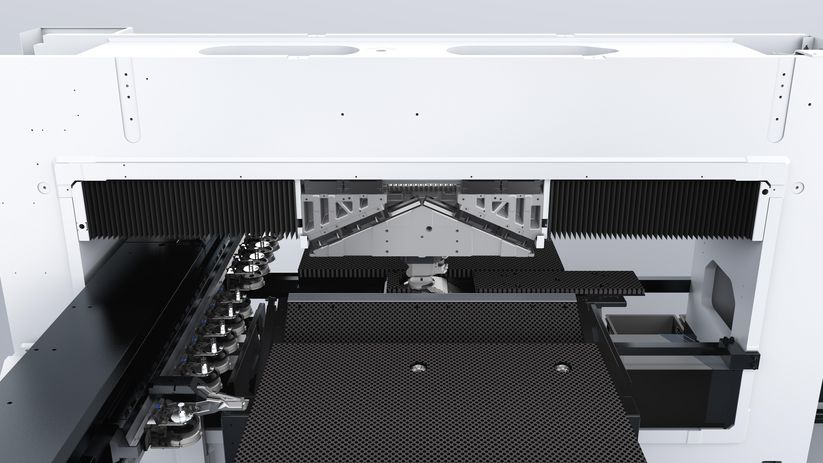

The descending die enables low-scratch punching and forming processes and prevents the risk of things getting caught.

When punching sheet metals, compression and tensile stresses are placed on the workpiece which can cause sheet deformation. The "Integrated flattening" machine function and the corresponding tool make it possible to even out surface irregularities during the punching process itself.

Ball tables or brush tables are available for gentle material handling.

Simple operation

Programming punching parts can be very easy – the new Touchpoint-HMI from TRUMPF makes machine operation as intuitive as using a tablet or smartphone. It helps you finish the part much more quickly – and even novices will quickly learn how to work with the software.

Process reliability

A large part removal flap enables automated unloading of parts up to a size of 400 x 600 mm. A sensor at the part removal flap detects whether parts have been caught in the scrap skeleton. This means you can reliably remove parts to containers, europallets or conveyor belts in both punching and laser operation.

Your machine automatically sorts parts up to a size of 180 x 180 mm. Finished parts go through a chute into an intermediate buffer storage. There are up to four different boxes under the machine. The intermediate buffer storage moves to the correct box and adds the parts to this.

Before a tool change, this function checks whether a hole has actually been punched in the sheet. In this way, the machine detects at an early stage when punches are broken, and can pass this information on to the operator. The smart punch monitoring function therefore avoids rejects, especially during night or weekend shifts.

Parts that are removed via the large part removal flap can be transported into boxes via conveyor belts.

The chip conveyor can be used to automatically transport punching slugs into a container.

Seamless integration of many TRUMPF machines into your own software environment is very easy. We have the right solution for every combination, whether it be integration into Oseon or a connection to monitoring and analysis tools. A connection to third-party software systems is also possible with our interfaces based on the OPC UA standard.

Sustainability

Compact, dynamic, and energy-efficient – the patented Delta Drive takes away the need for the sheet and support table to move in the Y axis because it enables the punching head to "fly", i.e. to move back and forth, for the very first time. In addition, the electric punch drive saves significantly more energy in comparison with hydraulically driven punching machines

TruTops Boost

Construct and program your laser, punching and combination punch laser machines intelligently with TruTops Boost, your all-in-one 3D solution. Numerous automated processes save you time-consuming routine processes and the joint nesting pool saves time and material. You also always have an overview of all manufacturing orders and order-based work.

Software

The software portfolio from TRUMPF optimises your entire production process – from the customer query to delivery of the finished part. TRUMPF combines the software intelligently with machines and services to create customised Industry 4.0 solutions for your Smart Factory.

You can boost the productivity of your punching machine with a tool adapter for up to ten inserts – in particular for small punching operations.

90° bends of different lengths up to 55 mm: when working with the MultiBend, there is no need for an additional operation on the bending machine.

The descending die enables a scratch-free punching and forming operation and prevents the risk of things getting caught.

TRUMPF offers the world's largest range of punching tools on the market. You will find the perfect solution for every punching and forming application.

Bring clarity to your procedures with our automation solutions. Employees can concentrate on their core tasks and customers will value you as a reliable supplier. You can produce more cost-effectively and gain financial flexibility.

Loading and unloading

The SheetMaster Compact takes over the reliable loading of sheets as well as the unloading of microjoint sheets and scrap skeletons. In this way, the machine operates completely automatically, if required, with a load capacity of up to three tonnes. This increases productivity and also relieves the strain on the operator.

Sorting

The SortMaster Compact removes and sorts the parts from your punch laser machine fully automatically. Especially when it comes to small and complex parts, the individually controllable suction cups make it possible to remove parts in the optimum way. Due to the minimal installation area, no extra space is required.

This product range and information may vary depending on the country. Subject to changes to technology, equipment, price and range of accessories. Please get in touch with your local contact person to find out whether the product is available in your country.