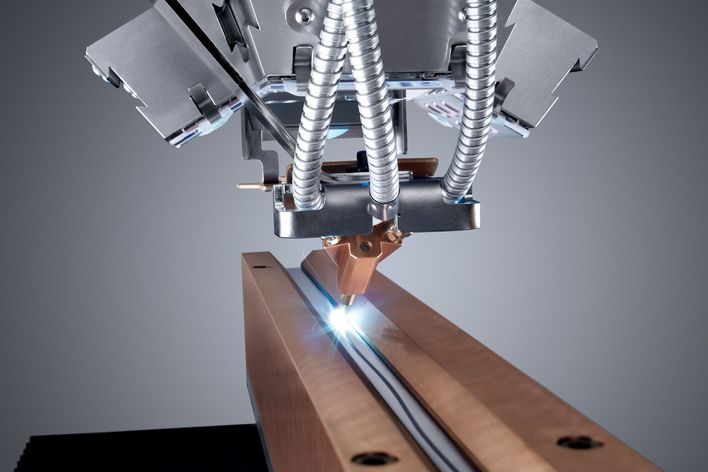

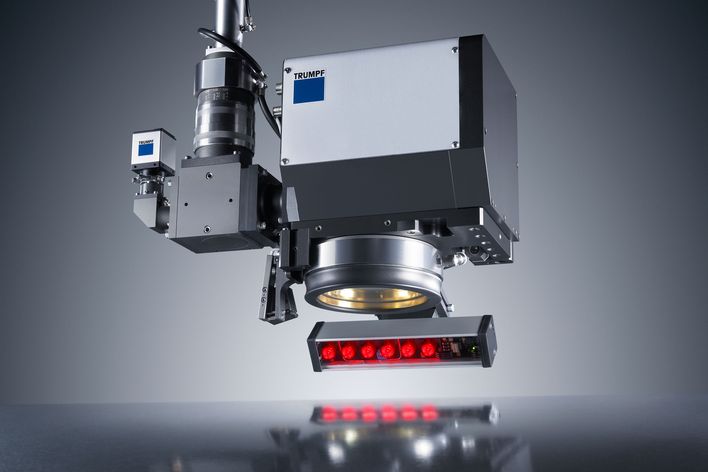

SeamLine Pro

Before, during and after welding, SeamLine Pro continuously gathers data for completely reproducible results. The comprehensive process sensor system monitors the entire welding process and at the same time records the seam point, the focal spot and the weld seam. A key advantage is that SeamLine Pro automatically adjusts the focal point at any time. Following welding, the sensor system checks the seam height and width, as well as edge offset.