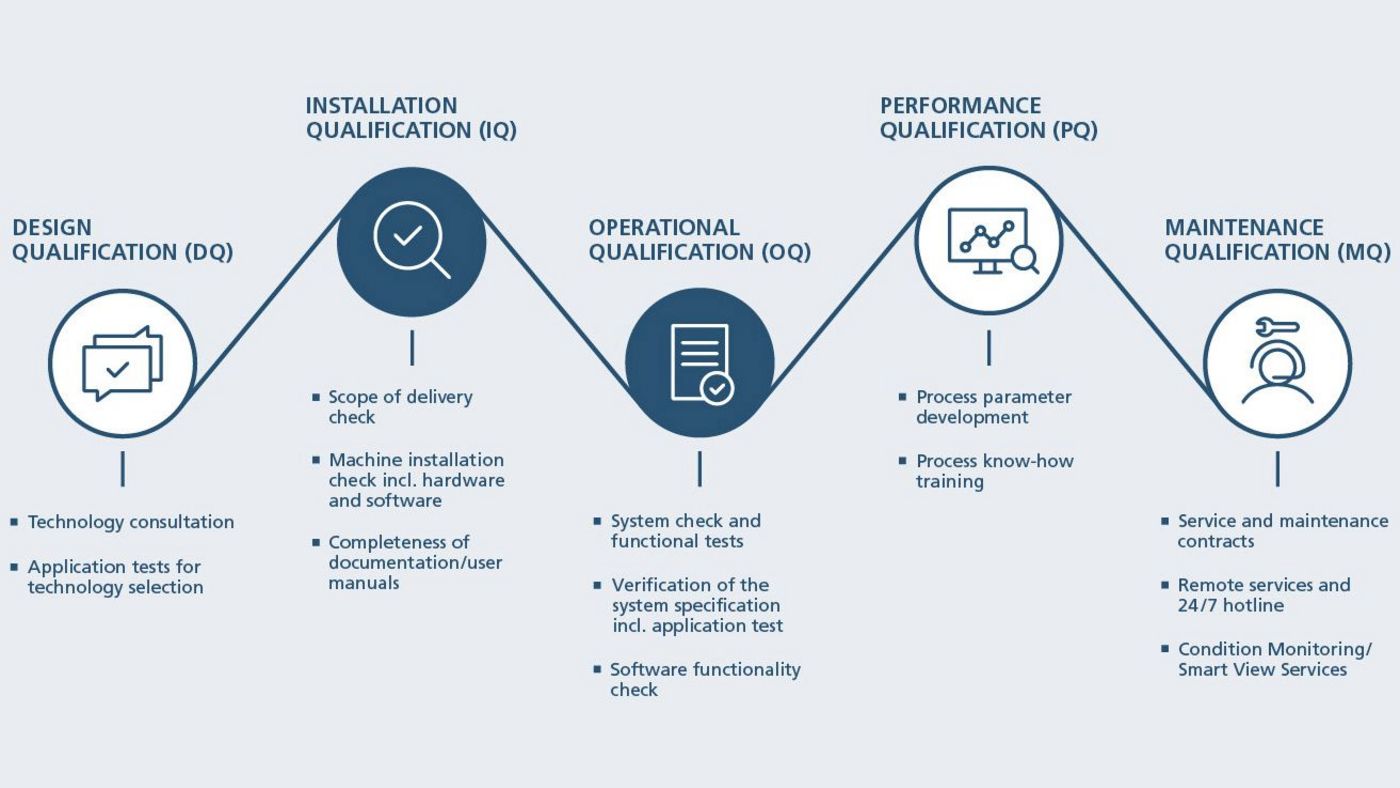

It can be quite challenging to have your laser system certified in regulated industries. Not with TRUMPF qualification experts who provide you time- and cost-saving support throughout the qualification process and constantly continue to develop your range. Our focus is on the particularly comprehensive standards and requirements from the medical technology and aviation and aerospace sectors. This way, our services are oriented primarily toward the requirements of the following standards and institutions: ISO/ASTM 52941 / 52942, ISO 13485, ISO 9100, FDA, NADCAP, and more.

Compliant installation and qualification of laser systems in regulated industries with TRUMPF expertise

You can count on our comprehensive tests, measurements, and detailed documentation when it comes to preparing your system for certification. We carry out application tests for feasibility and find qualified parameters together to ensure the corrosion resistance to certain materials, among other things.

Within the framework of TRUMPF IQ/OQ services, we take all critical aspects of the installation and function of your machine into consideration in a standardised process. The stability of the laser processing procedure is additionally supported by the TRUMPF PQ/MQ service.

As well as the time-efficient machine qualification, we support you with optimum integration into your digital production environment, for example, inclusion in your ERP system.

With our extended maintenance services you'll hold in-depth knowledge about the status of your system – every year.

Together with you, we will make sure that your system retains its certified condition, even after repairs.

We offer you the following services

We support you in the selection of the production technology which is best for you.

Contents

- Advice on the process and material processing

- Application tests for technology selection

- Customer-specific specialised solutions

Your advantages

- Foundation for successful equipment qualification

- Suitable economic and technical solutions in accordance with individual requirements

We check whether your system has been delivered and installed as ordered.

Contents

- Review of the scope of delivery

- Inspection of the machine installation, incl. hardware & software

- Completeness of the documentation

- IQ report

Your advantages

- Time-efficient inspection of the scope of delivery and correct system installation by an expert

We check your system for full functionality in accordance with the specified requirements.

Contents

- System check & function checks

- Inspection of safety functions

- Verification of system specifications

- Software functionality check

- Application tests

- Test report & OQ report

Your advantages

- Safeguarding of the entire machine's specifications as defined in the DQ

- Time-efficient documentation of the specifications by an expert

- Ensuring the faultless operation of the machine for the start of the PQ

We inspect your system for reliable and replicable production results.

Contents

- Implementation of application tests to determine the process limits

- Relaying of process expertise to staff

Your advantages

- Obtainment of high quality and additional productivity by finely adjusting the parameters

- Competently trained employees with outstanding product and process knowledge for permanently stable and efficient production processes

We support smooth series operation of your system with maintenance and repair services.

Contents

- Training courses on operation & maintenance of the system

- Maintenance and service agreements

- Remote Service and 24/7 Hotline

- Support during application tests

- System condition check

- Maintenance of machine qualification by checking and calibrating all process-relevant individual functions of the machine

- Consistent and detailed documentation of all measurement results

Your advantages

- High machine availability in production thanks to the services on offer and TRUMPF's worldwide presence

- Lasting use of the machines within the established customer process thanks to long-term availability of spare parts

- Competently trained employees ensure – with internally implemented maintenance – stable and productive production processes

Our customers say ...

We offer qualification support for the following systems*:

after consultation:

- TruPrint 1000

- TruPrint 2000

- TruPrint 3000

- TruPrint 5000

The qualification support is primarily possible for all of our TruPrint machines. However, to respond to individual requirements, it is always necessary to consult with the responsible experts at TRUMPF.

- TruMark Station 5000 + TruMark 3230 and TruMark 3330

- TruMark Station 5000 + TruMark 5020 and TruMark 5050

- TruMark Station 5000 + TruMark 6030

- TruMark Station 70001 + TruMicro Mark 2030

- TruMark Station 70001 + TruMark 3330

- TruMark Station 70001 + TruMark 5050

- TruMark Station 70001 + TruMark 6030

1only with TruMark Station lifting door

- TruLaser Station 7000 + TruDisk

- TruLaser Station 7000 + TruFiber

- TruLaser Station 7000 + TruDiode

- TruLaser Station 7000 + TruPulse

*The supported systems may vary depending on the country. Please contact us.