In tomorrow’s smart factories, it will be the machines that call out their capacities, control the results of their own work and ask raw materials and products who they are and what is to be done with them. Achieving the smart factory is one of the goals of the German government’s Industrie 4.0 initiative, and other highly industrialized countries have adopted similar initiatives.

Giving a machine more “brain” is a massive job, encompassing software, sensors and automation – not to mention software and hardware interfaces for exchanging data. According to Jörg Smolenski, who is responsible for marketing and sales for the ML1 marking laser, “There’s never a shortage of space for those kinds of components in the machines. Where we do run out of space is on the workpiece: The question is, where’s the room on a newly hatched part for the brains that would allow it to communicate with the next set of machines?”

Smolenski has a simple answer: A workpiece doesn’t need a brain if it is sent out into the world with identity papers in the form of a clear marking. “Then all that’s left is for each machine to be able to set, read and replace markings. This can be achieved very easily using a data matrix or a QR code – and it saves a lot of space, too.”

Traceability Becomes Industry 4.0

In the German city of Tuttlingen, engineers at Chiron, a company that builds vertical CNC machining centers, have seized on the idea of automatic marking. As Thomas Marquardt, the company’s head of automation, puts it: “Even if it’s not specifically about Industry 4.0, it’s very important to our customers that their products can be identified and traced from the very first workstation. That’s often a condition for landing a contact in the first place.”

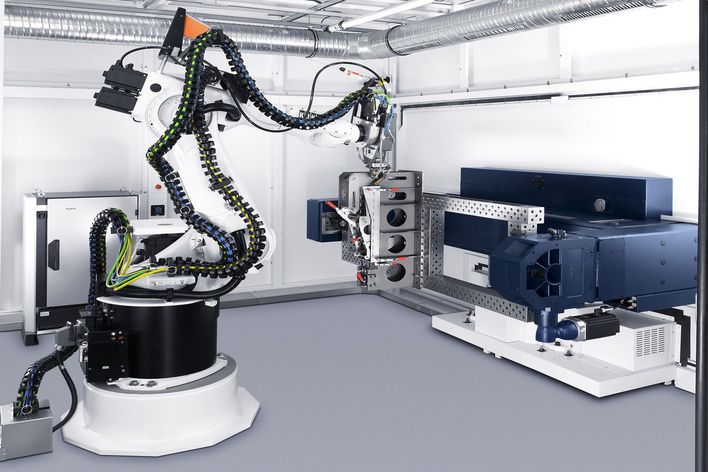

This explains why Chiron set out to find a solution that would make custom marking a natural part of what the machine does. Chiron showcased the result – a FLEXCELL UNO type automated manufacturing cell with a permanently integrated marking station and in-process measuring station – at its open house event in May this year and will be doing so again soon at AMB 2014 in Stuttgart.

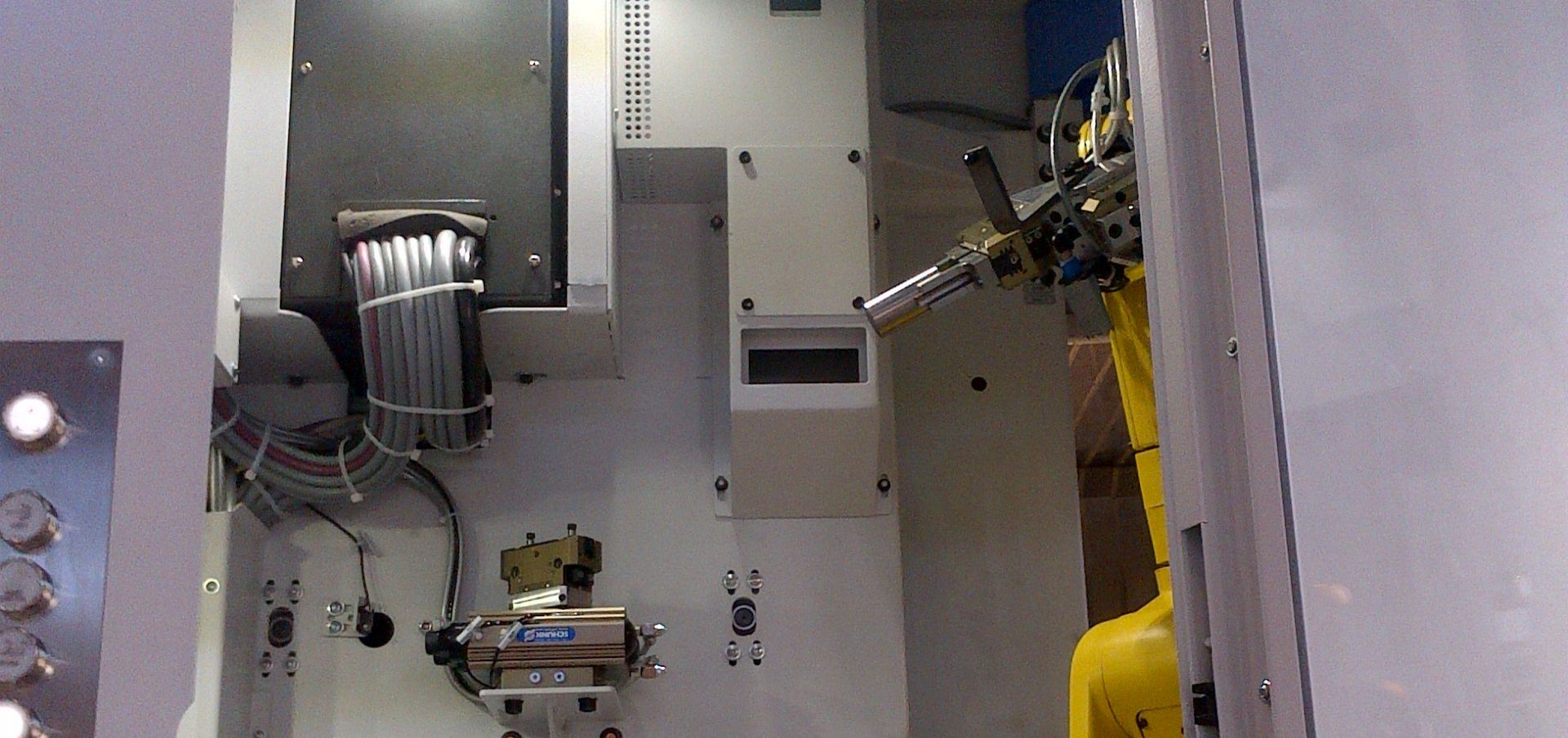

In this setup, the handling robot in the CHIRON FLEXCELL UNO first places the finished part into the measuring station, where the workpiece is measured. The robot then transfers the part to the marking station, where – providing the measuring data are perfect – the machine marks its product as a finished part, perhaps giving it a data matrix code that stores key manufacturing data or a reference number for the part such as a series or batch number.

The Code that Says Everything

“Standard manufacturing data might include date of manufacture, machining station, supplier number and order number,” explains Marquardt. “But it’s also possible to include other codes in the marking, of course.” For instance, these codes could tell a transport system where the part needs to go or inform the next machining station’s control system which program to start. This is how traceability becomes Industry 4.0.

Although it’s an ML1 marking laser that does the marking, as far as future customers of the machining center are concerned everything comes from Chiron – including the laser. ML1 is more than an extremely compact and easy-to-integrate marking laser: Customers who are confident that they will achieve certain batch sizes with their series machine can even have the laser sport their own design and name, and buy in the necessary know-how for installing, applying, calibrating and servicing it as part of the product package.

Marquard sees this as a major plus. “This deep integration helps combat reservations about lasers and at the same time stresses our expertise in the minds of customers. It turns a marking station into just another equipment option that we manage ourselves.”

The Database that Knows Everything

In Loßburg, only around 70 kilometers north of Tuttlingen, ARBURG engineers and developers have been tackling the same questions. Drawing inspiration from the company’s history as well as its product range, they incorporated a database into their solution that takes a large step toward Industry 4.0.

Oliver Giesen, head of projects in Loßburg, explains: “ARBURG’s host computer system (ALS) gives you the option of storing all relevant manufacturing and quality assurance data for each individual part.” That way, the code doesn’t even have to store manufacturing data. Instead, it holds the link to the part’s history stored in the database.

Film Industry 4.0 – integrated, personalised production

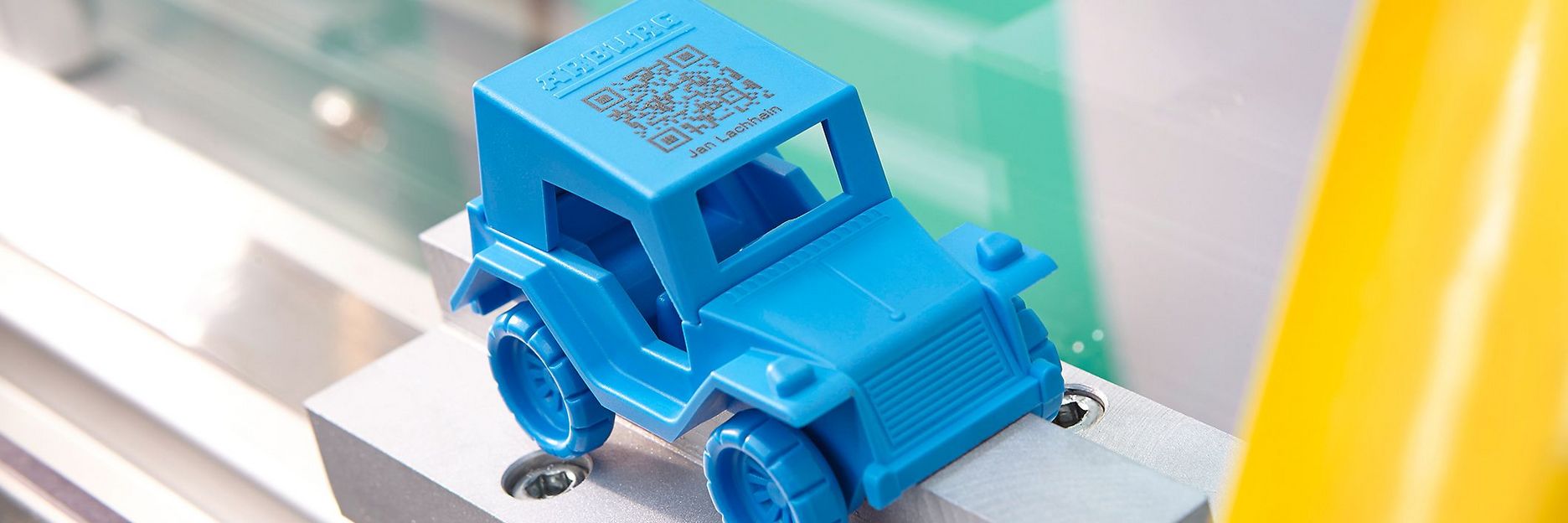

ARBURG demonstrated exactly what this interplay of database, machine, quality assurance and marking looks like in spring 2014, also at one of the company’s open house events. Using a custom chip card, visitors were given the chance to have the parts for a toy buggy made. Before leaving the manufacturing cell, the roof of each future buggy was given a laser-marked QR code. At the same time, the machine control system deposited all manufacturing parameters in the ALS database and assigned them to the relevant code.

The Laser Which Does Not Call for Your Attention

Once visitors had assembled their buggies, an automated quality assurance system checked and documented the result. Using the QR code, the ALS then immediately matched the results to the right buggy.

To make all this work the machine still needs a marking laser, albeit in somewhat of a supporting role. “It’s not the hero of our story,” admits Oliver Giesen. From his customers’ point of view, the marking laser is meant to be only a small, unobtrusive helper – something that is just there and something that customers ideally don’t have to worry about. “As if it were nothing more than a lamp,” says Giesen.

Integrated to the Point of Being Invisible

Of course, a marking laser such as the ML1 is a lot more complex than a simple lamp. But according to Jörg Smolenski, the comparison neatly sums up the idea behind the integration and branding program for ML1 series machines.

Marking-laser hardware is a firmly established closed system comprising easily built-in components – PC, electronics, laser source and lens. And with its standardized interfaces, for instance to SAP or Microsoft Office, the software used is clearly heading in the same direction. Up to now, TRUMPF technicians have been a fixture of the integration phase, bringing the company’s expertise in the interaction of laser light and materials.

In many cases it is an advantage to let the laser supplier manage any laser issues. “But the picture changes once a manufacturer decides to offer marking lasers as a standard option,” says Smolenski. “At that point, it makes more sense not to have a third party working with you on your machine. And we make this possible with the ML1 and the option of integrating it carrying your brand.”

No matter whether your focus is on traceability or Industry 4.0, the “talkative” product is already a series-production reality. And it’s a step toward the smart factory, even if there is still a lot to do before the robotic arm asks the production hall: “Are you still reading or shall I turn out the light?”

Contact:

Jörg Smolenski ; +49 715630330144; lasermarking@trumpf.com

Laser, scanner, control unit and even applications expert: The ML1 marking laser is a complete marking system designed for easy and complete integration. It offers all essential industrial interfaces – even a printer driver for marking directly from MS Office applications – and user-specific software can be integrated easily. Weighing just 12 kilograms and with an extremely compact housing, the ML1 marking laser fits in anywhere. You can even give the housing your own custom look.

Get more information about the ML1 marking laser by contacting Jörg Smolenski: lasermarking@trumpf.com

Founded in 1921 as a machine shop, today CHIRON is a world leader in the field of vertical CNC manufacturing centers and related turnkey solutions.

Arburg is one of the world’s leading manufacturers of injection molding machines that feature clamping forces between 125 and 5,000 kN. The company’s portfolio also includes robot systems, customer-specific and sector-specific turnkey solutions and much more besides.