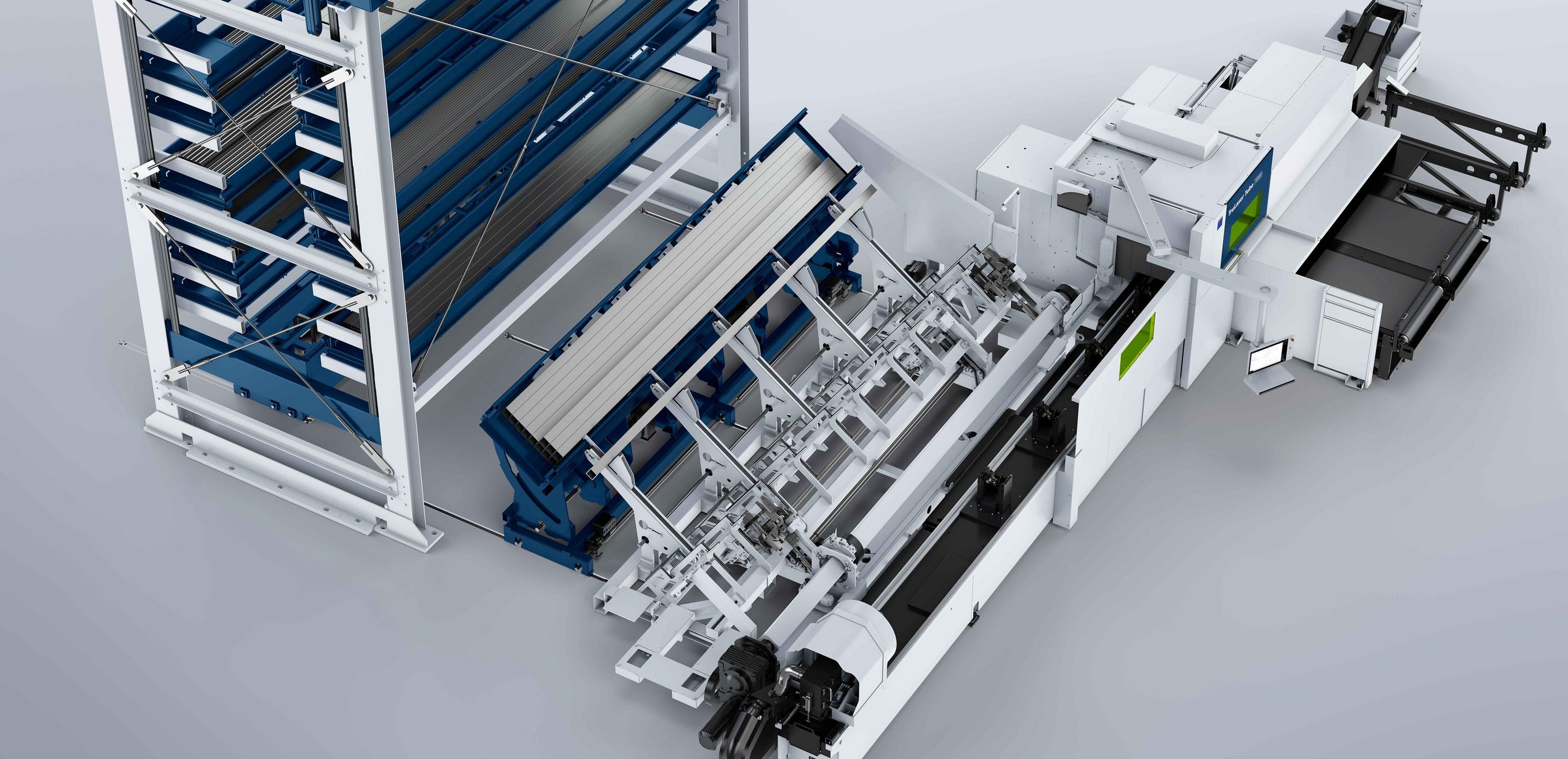

Tube storage system with a storage connection

Reduce operator involvement in your tube processing operation. The tube store with a storage connection allows you to benefit from fast, automatic raw material changes. The increased degree of automation is an important step towards fully automated production and a properly structured storage system.

The automatic supply of tubes relieves the workload on qualified personnel.

The machine is automatically fed from a STOPA tube storage system.

The automation removes a defined number of tubes from the storage cassette.

Load your laser tube-cutting machine fully automatically and unattended.

Load tubes automatically and reduce operator intervention using TRUMPF's tube store with a storage connection.

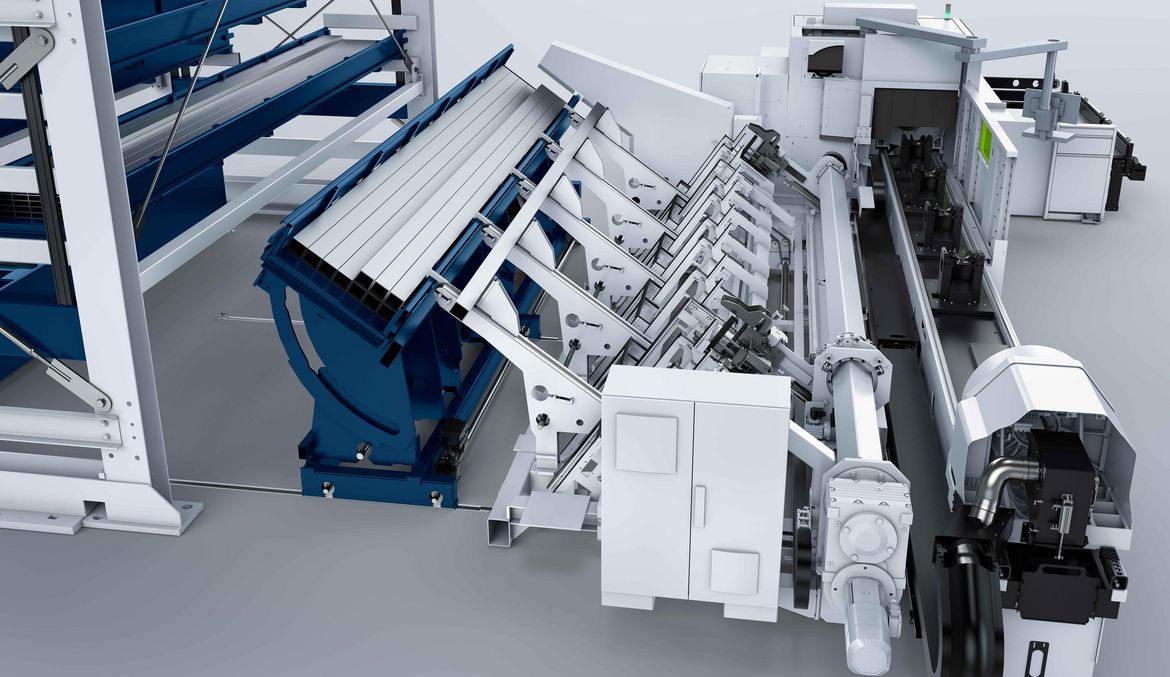

Flexibility is provided by a swivel-mounted conveyor system, which allows the TruLaser Tube machine to be loaded semi-automatically with special profiles and intermediate orders without prior storage.

The tilt-and-lift station takes the cartridge with the raw material from the STOPA store and transfers it to the conveyor unit.

Process chain for tube processing

A fully automated tube processing chain prevents skills shortages, saves money and cuts operating errors.

Automated loading and unloading

Load and unload your machines fully automatically and reduce operator involvement.

Tilt-and-lift station with LoadMaster Tube on the TruLaser Tube 5000 fiber

The tilt-and-lift station takes the cartridge with the raw material from the store and transports it to the conveyor unit, which is connected to the LoadMaster Tube. There, the tubes are lifted out of the cassette, separated and transferred to the LoadMaster Tube.

Tilt-and-lift station with LoadMaster Tube on the TruLaser Tube 7000 fiber

The tilt-and-lift station takes the cartridge with the raw material from the store and transports it to the conveyor unit, which is connected to the LoadMaster Tube. There, the tubes are lifted out of the cassette, separated and transferred to the LoadMaster Tube.

This product range and information may vary depending on the country. Subject to changes to technology, equipment, price and range of accessories. Please get in touch with your local contact person to find out whether the product is available in your country.