For heavy-duty tasks

The TruTool S 450 is equipped with a robust cutting table specifically designed for thick sheet. This enables you to produce high-quality cuts in sheet thicknesses of up to 4.5 mm. Above all, the machine is particularly well-suited for processing stainless steel up to 2.5 mm. You can cut radii starting from 35 mm without force. With a working speed of 6 metres per minute, production is quick. This is particularly advantageous when processing large sheets. The blades can be adjusted quickly and easily to the sheet thickness using a rotary knob.

Powerful 1700 W motor with a cutting table specifically designed for thick sheet.

The height adjustment of the blades enables individual adaptation to the sheet thickness.

The bow-handle for one-hand and two-hand operation ensures reliable machine control.

The blades each have two cutting edges and can be used either at the top or bottom.

Flat sheet

Cutting and trimming of straight sheets. For radial and interior cutouts as well as notching.

Coil processing

For cutting coils. For relief cuts and sampling.

Grids

For cutting a wide variety of wire grids.

The following consumables and the corresponding accessories are included in the scope of delivery.

Find the right consumables and accessories for your machine here.

For high-tensile sheets up to 800 N/mm2

For steel up to 400 N/mm2

Pedestal for work station

For the stationary processing of small workpieces and wire grids.

For the stationary processing of small workpieces and wire grids

Height adjustment without tools

Two-way blade rotation

Optimal working speed

|

TruTool S 450

|

|

|---|---|

| Maximum sheet thicknesses | |

| Maximum sheet thickness, steel 400 N/mm² | 4.5 mm |

| Maximum sheet thickness, steel 600 N/mm² | 3.5 mm |

| Maximum sheet thickness, steel 800 N/mm² | 2.5 mm |

| Maximum sheet thickness, aluminium up to 250 N/mm² | 5 mm |

| Radii | |

| Smallest radius | L 35 mm / R 25 mm |

| General | |

| Working speed (max.) | 6 m/min |

| Starting hole diameter | 75 mm |

| Nominal power consumption | 1700 W |

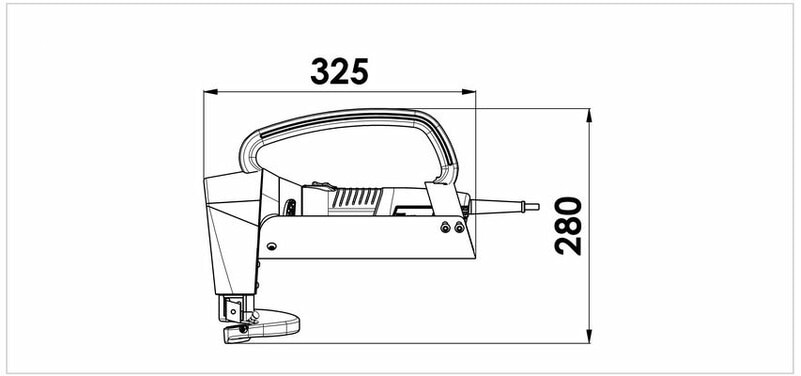

| Dimensions | |

| Length | 325 mm |

| Height | 280 mm |

| Weight | |

| Weight | 6.2 kg |

The technical data of all product versions as a download.

This product range and information may vary depending on the country. Subject to changes to technology, equipment, price and range of accessories. Please get in touch with your local contact person to find out whether the product is available in your country.