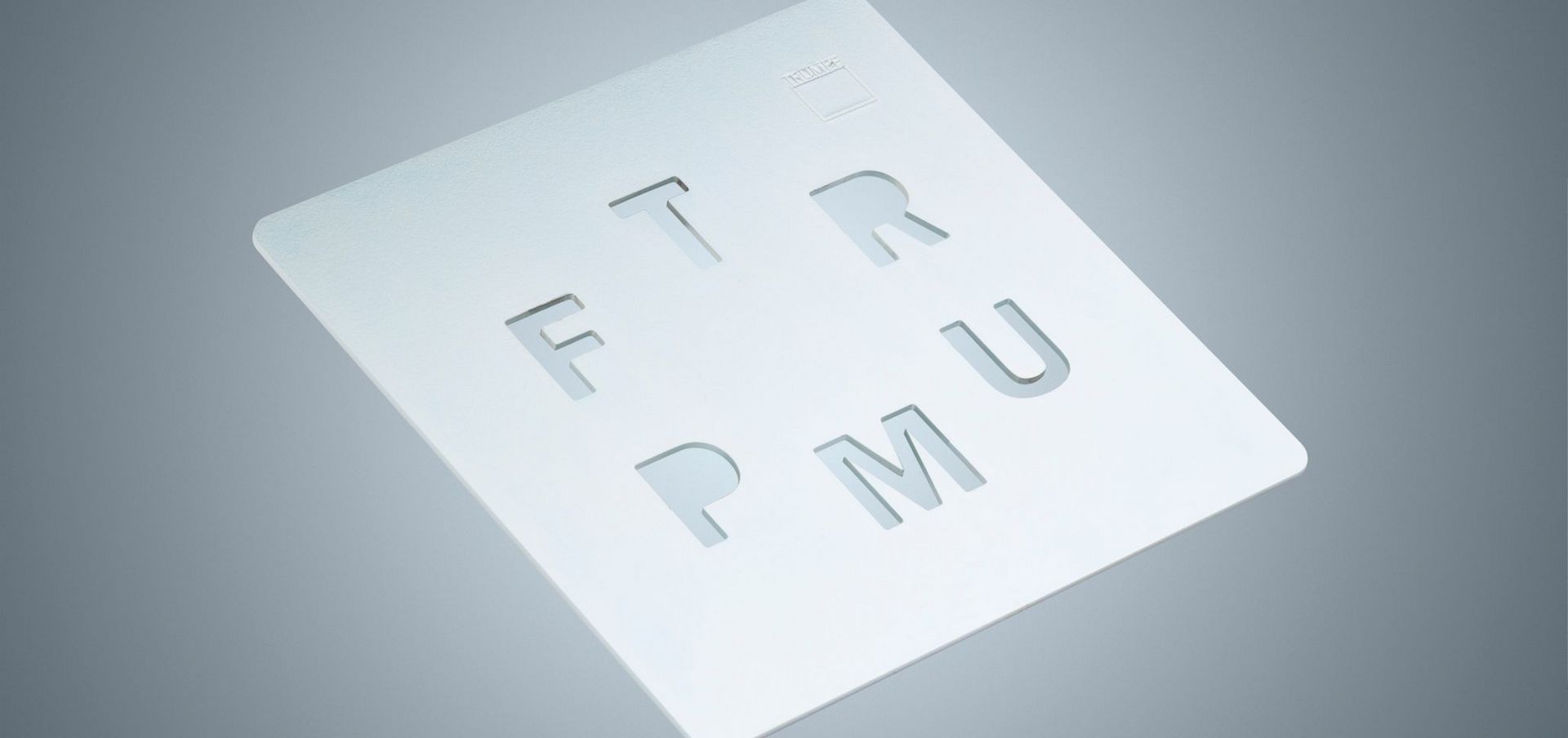

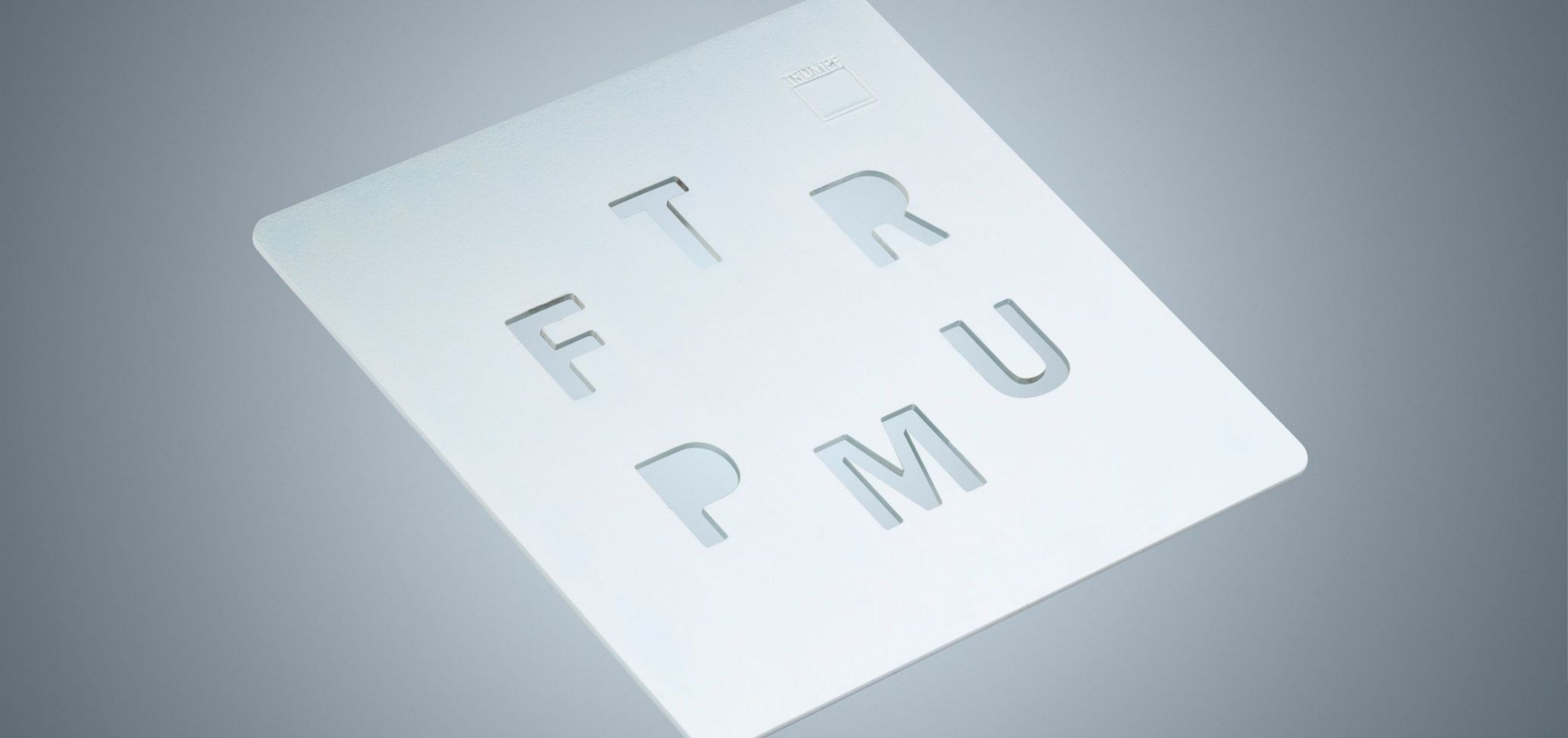

For small, laser-cut sheet metal parts with complex geometries, removal via the part removal flap or disposal through the laser console is often not possible as the parts can easily tilt in the sheet and remain stuck in the scrap skeleton. Using the ejector MultiTool, you can quickly eject these parts through the die into the punching console with process reliability. Here, the microjoint strip is separated with the ejector punch in a single stroke. The punch has five different round or rectangular inserts, suitable for every part geometry. This means you can process both round as well as straight contours without changing the tool.

Reliable removal with minimal setup time

The ejector MultiTool enables the reliable removal of small laser-cut parts from your punch laser machine with minimal tool change times. Microjoints with different geometries are separated reliably and ejected through the die into the punching console.

Fast with process reliability

Remove laser-cut small parts quickly and with process reliability in microjoint technology.

Flexible with minimal setup time

Ejection of round or straight contours without a tool change due to five different punch inserts.

Smooth processing

Excellent gear rim rotational properties due to a special coating.

Tool options

Contact