Kawaguchi - a city north of Tokyo and the location of many small industrial factories known in Japan as machi-kōba. In these factories, employees produce products of all kinds, from commodities to industrial goods. The factories have one goal in common: they want to overcome their dusty image and show off their craftsmanship. After all, often not even the nearest residents know what is being created in their production halls. To change this, the Machi-kōba in Kawaguchi open their factories to the residents of the city. At these open factory events, every visitor gets an insight and learns what products are created in their own hometown.

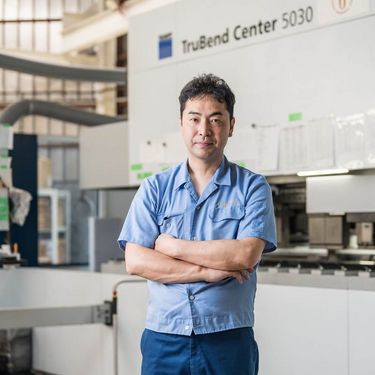

Ryuichi Yoshida also opens the doors of his factory on these days. He has been President of the Japanese industrial company KANEYOSHI Co. for twelve years. In his production hall, visitors can marvel at a very special product.

Work of art on three legs

Normally, KANEYOSHI supplies individual industrial components to various industries - from the food industry to medical technology. The company specializes in the production techniques of bending and welding and uses TRUMPF machines for this purpose. Recently, however, something else has been created on these machines: Japanese designer Kazuhito Ishida is creating a work of art in KANEYOSHI's production hall that is intended to serve a special purpose. "KANEYOSHI is supporting me in transforming abstract technologies into a piece of domestic furniture. This way, people can experience the beauty of metal firsthand and understand the craft," says Ishida, describing his idea. The domestic piece of furniture is a chair called an "Orisu."

From a piece of sheet metal to a work of art

KANEYOSHI manufactures Ishida's design with TRUMPF machines. This offers advantages: "On TRUMPF machines, I can use different manufacturing processes within a short time. This allows me to finish the product faster," Yoshida explains. The production of the chair shows what the KANEYOSHI company is capable of: First, lasers cut uniform components from sheet metal. When bent in the right places and welded together, these components finally make up the finished object like puzzle pieces. The designer and Yoshida choose the material quite deliberately: "Unlike wooden products, sheet metal has the advantage that its strength can be increased simply by bending it. So we don't need any additional components to assemble the chair. This saves material and weight," explains Ishida.

Yoshida is happy about his new perspective

KANEYOSHI President Ryuichi Yoshida has known his new cooperation partner for some time: "As a student, I took part in a project at a design school. Kazuhito was my teacher," recounted Yoshida. This encounter led to Yoshida's involvement in an art project with Ishida as the designer. Working with the designer has changed Yoshida's work: "Normally, we supply individual components. Making a final product changed my perspective. I now put myself in the perspective of the people who end up using the product."

Yoshida has acquired a taste for it: He is already working with Ishida on new art projects. Ishida is looking forward to that, too: "We've known each other for a long time. Ryuichi understands what I think, and we always agree. I hope that our collaboration will continue to produce many new works in the future."

Ryuichi Yoshida, President of KANEYOSHI, is happy about his new perspective. The art project has changed his work. He is planning more projects with designer Kazuhito Ishida in the future.

A city in transition

Yoshida is not the only one who has come to art in Kawaguchi: every year, the factories organize the Kawaguchi Machi-kōba Art Festival, of which Kazuhito Ishida has been the Director since last year. The festival features a variety of artworks created in collaboration between the factories and designers. "Art enriches people's lives. It may not be necessary for survival in the face of current crises, but it always manages to put a smile on people's faces," Ishida told us. Thus, the Japanese city of Kawaguchi is undergoing a special transformation: from a classic industrial city with a dusty image to a place for design and art; a place where people go to feel good.

Since 1953, the Japanese industrial company KANEYOSHI Co. has been supplying individual industrial components to more than 1,500 customers from a wide range of industries - from the food industry to medical technology. This traditional company specializes in the production techniques of bending and welding and uses TRUMPF machines for this purpose. KANEYOSHI is characterized by the fact that they respond to individual customer requests and produce for both private customers and large customers. Ryuichi Yoshida (pictured left) has been president of the company for 12 years. His production hall now houses 14 TRUMPF machines, including five laser cutting machines and five bending machines. In total, the company employs 45 people (as of 2022).