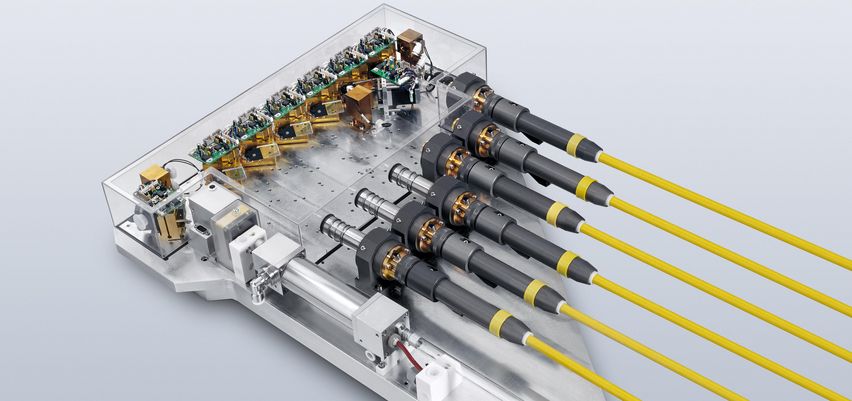

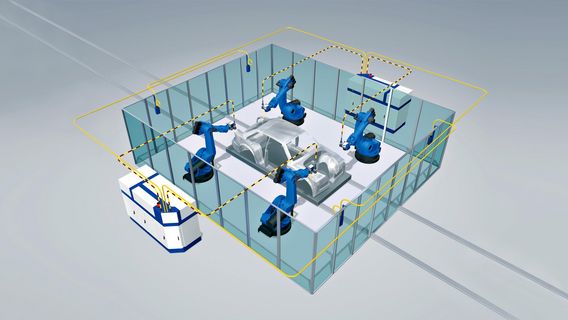

Thanks to its integrated beam guidance, the TruPulse can be perfectly adapted to your application. With up to six pluggable laser outlets and a flexibly configurable beam distribution, the laser beam can be split, switched over, disabled and measured. This makes it possible to use the solid-state laser at one or more processing stations, optionally with a time or energy split. This enables multiple welding processes to be performed in parallel or at staggered times. The modular layout enables subsequent repairs or upgrades in the field.

Sophisticated power pack

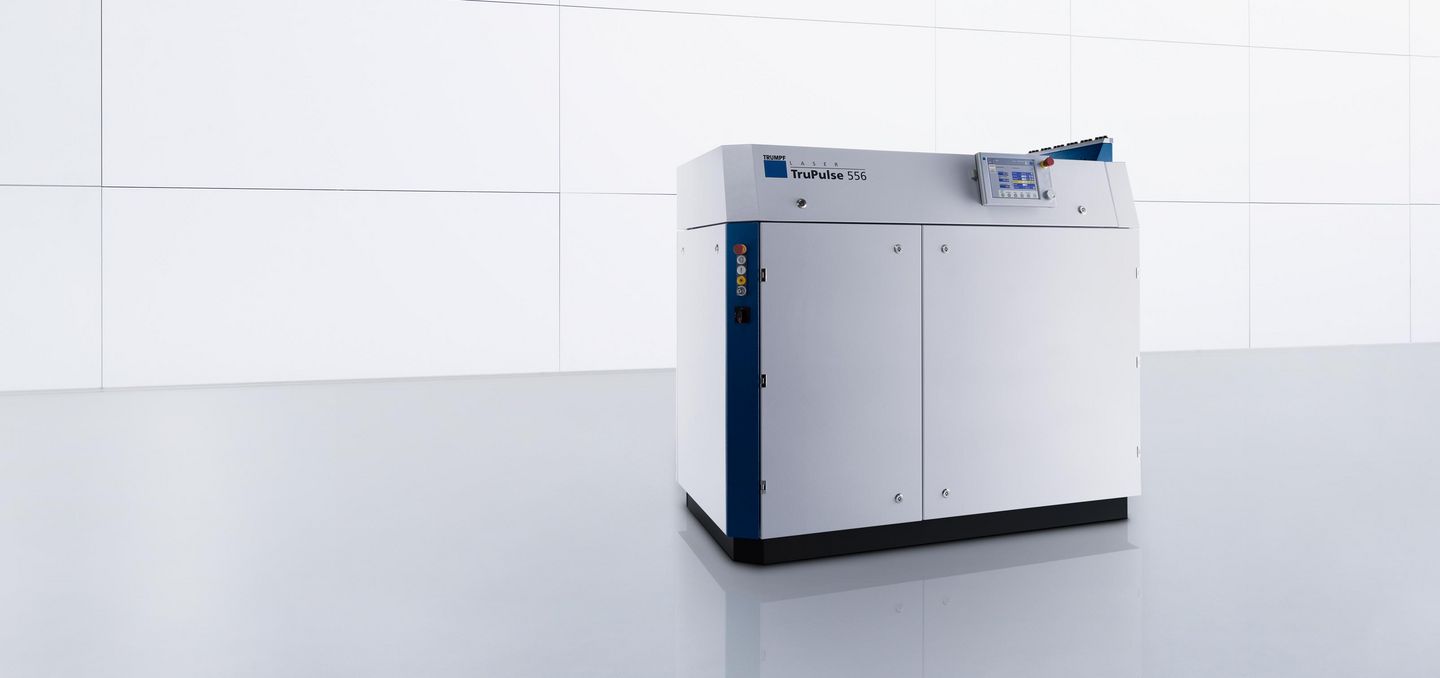

The tried-and-tested pulsed solid-state lasers in the TruPulse series enable short, high-energy pulses at high power. The pulse power of several kilowatts for a few milliseconds means that spot welding and seam welding are now also possible in places where other methods fail. Thermally sensitive applications in particular benefit from the advantages of pulsed solid-state lasers. Thanks to their modular design, the lasers can be flexibly adapted to your individual manufacturing task. The TruPulse series has been technically optimised over decades, making the system highly reliable as a result.

Individually adaptable lasers due to the broad product portfolio and the modular design of the TruPulse

The real time laser power control means that exactly the power you select arrives at the workpiece.

The laser compares the pulse shape you have chosen with the actual pulse shape in a 10 μs cycle.

With the burst function you can temporarily increase the average power several times over.

The WeldAssist option provides suggestions for all of the process parameters depending on the material and welding depth.

Endoscopic instrument

High precision is vital for medical instruments. The TruPulse is perfectly suited to these applications. The welding seams on this endoscope are barely visible.

Electronic plug

Electronic plug contacts are often reshaped and then fixed in place with the laser. The reliability of the TruPulse lasers ensures highly productive 3-shift operation with reject rates of less than a percent.

Sensor module

The low heat input resulting from the pulsed laser process protects the sensitive electronics of the power sensor module, which was seam welded with the TruPulse.

Optoelectronic component

The cover of an optoelectronic component is attached to a housing by means of pulsed seam welding.

Plug

With the aid of the burst mode function, the processing time for welding the plug is reduced by 70%. This is implemented by means of fast beam positioning via PFO scanner optics, paired with the capability of the TruPulse laser to emit multi-kW pulses with an increased frequency for short bursts.

|

TruPulse 21

Compare product

|

TruPulse 33

Compare product

|

TruPulse 44

Compare product

|

TruPulse 62

Compare product

|

TruPulse 74

Compare product

|

TruPulse 103

Compare product

|

TruPulse 106

Compare product

|

TruPulse 124

Compare product

|

TruPulse 156

Compare product

|

TruPulse 203

Compare product

|

TruPulse 304

Compare product

|

TruPulse 556

Compare product

|

|

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Laser parameters | ||||||||||||

| Laser power at the workpiece | 20 W | 30 W | 40 W |

60 W

65 W |

70 W |

90 W

95 W |

110 W |

110 W

125 W 140 W |

140 W

150 W 160 W |

200 W | 300 W | 530 W |

| Max. peak pulse power | 1.5 kW | 3 kW | 3 kW |

3 kW

5 kW |

4 kW

6 kW |

5 kW

6 kW 8 kW |

4 kW |

6 kW

9 kW |

6 kW

10 kW |

6 kW

8 kW |

10 kW | 10 kW |

| Beam quality | 4 mm▪mrad | 12 mm▪mrad | 16 mm▪mrad | 8 mm▪mrad | 16 mm▪mrad | 12 mm▪mrad | 25 mm▪mrad | 16 mm▪mrad | 25 mm▪mrad | 12 mm▪mrad | 16 mm▪mrad | 25 mm▪mrad |

| Wavelength | 1064 nm | 1064 nm | 1064 nm | 1064 nm | 1064 nm | 1064 nm | 1064 nm | 1064 nm | 1064 nm | 1064 nm | 1064 nm | 1064 nm |

| Adjustable pulse duration | 0.2 ms - 50 ms | 0.2 ms - 50 ms | 0.2 ms - 50 ms | 0.2 ms - 50 ms | 0.3 ms - 50 ms | 0.3 ms - 50 ms | 0.3 ms - 50 ms | 0.3 ms - 50 ms | 0.3 ms - 50 ms | 0.3 ms - 50 ms | 0.3 ms - 50 ms | 0.3 ms - 50 ms |

| Max. pulse sequence frequency | 909 Hz | 909 Hz | 909 Hz | 909 Hz | 833 Hz | 833 Hz | 833 Hz | 833 Hz | 833 Hz | 833 Hz | 833 Hz | 833 Hz |

| Max. pulse energy | 15 J | 30 J | 30 J |

20 J

50 J |

30 J

60 J |

30 J

60 J 90 J |

30 J |

30 J

70 J 90 J |

30 J

80 J 120 J |

55 J

90 J |

60 J

90 J |

60 J

100 J |

| Min. laser light cable diameter | 100 μm | 300 μm | 400 μm | 200 μm | 400 μm | 300 μm | 600 μm | 400 μm | 600 μm | 300 μm | 400 μm | 600 μm |

| Structural design | ||||||||||||

| Dimensions, basic version (W x H x D) | - | - | - | 980 mm x 1220 mm x 505 mm | 980 mm x 1220 mm x 505 mm | 980 mm x 1220 mm x 505 mm | - | 980 mm x 1220 mm x 505 mm | 980 mm x 1220 mm x 505 mm | - | 1500 mm x 1370 mm x 730 mm | 1500 mm x 1370 mm x 730 mm |

| Dimensions, extended version (W x H x D) | - | - | - | 980 mm x 1220 mm x 715 mm | 980 mm x 1220 mm x 715 mm | 980 mm x 1220 mm x 715 mm | - | 980 mm x 1220 mm x 715 mm | 980 mm x 1220 mm x 715 mm | - | 1500 mm x 1370 mm x 990 mm | 1500 mm x 1370 mm x 990 mm |

| Dimensions (W x H x D) | 485 mm x 700 mm x 800 mm | 485 mm x 700 mm x 800 mm | 485 mm x 700 mm x 800 mm | - | - | - | 980 mm x 1220 mm x 505 mm | - | - | 1500 mm x 1370 mm x 730 mm | - | - |

| Max. number of laser light cables | 3 | 3 | 3 | 6 | 6 | 6 | 3 | 6 | 6 | 6 | 6 | 6 |

| Installation | ||||||||||||

| Protection class (air cooling) | IP22 | IP22 | IP22 | IP22 | IP22 | IP22 | IP22 | IP22 | IP22 | - | - | - |

| Protection class (water cooling) | IP54 | IP54 | IP54 | IP54 | IP54 | IP54 | IP54 | IP54 | IP54 | IP54 | IP54 | IP54 |

| Ambient temperature (water cooling) | 10 °C - 40 °C | 10 °C - 40 °C | 10 °C - 40 °C | 10 °C - 40 °C | 10 °C - 40 °C | 10 °C - 40 °C | 10 °C - 40 °C | 10 °C - 40 °C | 10 °C - 40 °C | 10 °C - 40 °C | 10 °C - 40 °C | 10 °C - 40 °C |

|

TruPulse 21

|

TruPulse 33

|

TruPulse 44

|

TruPulse 62

|

TruPulse 74

|

TruPulse 103

|

TruPulse 106

|

TruPulse 124

|

TruPulse 156

|

TruPulse 203

|

TruPulse 304

|

TruPulse 556

|

|

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Laser parameters | ||||||||||||

| Laser power at the workpiece | 20 W | 30 W | 40 W |

60 W

65 W |

70 W |

90 W

95 W |

110 W |

110 W

125 W 140 W |

140 W

150 W 160 W |

200 W | 300 W | 530 W |

| Max. peak pulse power | 1.5 kW | 3 kW | 3 kW |

3 kW

5 kW |

4 kW

6 kW |

5 kW

6 kW 8 kW |

4 kW |

6 kW

9 kW |

6 kW

10 kW |

6 kW

8 kW |

10 kW | 10 kW |

| Beam quality | 4 mm▪mrad | 12 mm▪mrad | 16 mm▪mrad | 8 mm▪mrad | 16 mm▪mrad | 12 mm▪mrad | 25 mm▪mrad | 16 mm▪mrad | 25 mm▪mrad | 12 mm▪mrad | 16 mm▪mrad | 25 mm▪mrad |

| Wavelength | 1064 nm | 1064 nm | 1064 nm | 1064 nm | 1064 nm | 1064 nm | 1064 nm | 1064 nm | 1064 nm | 1064 nm | 1064 nm | 1064 nm |

| Adjustable pulse duration | 0.2 ms - 50 ms | 0.2 ms - 50 ms | 0.2 ms - 50 ms | 0.2 ms - 50 ms | 0.3 ms - 50 ms | 0.3 ms - 50 ms | 0.3 ms - 50 ms | 0.3 ms - 50 ms | 0.3 ms - 50 ms | 0.3 ms - 50 ms | 0.3 ms - 50 ms | 0.3 ms - 50 ms |

| Max. pulse sequence frequency | 909 Hz | 909 Hz | 909 Hz | 909 Hz | 833 Hz | 833 Hz | 833 Hz | 833 Hz | 833 Hz | 833 Hz | 833 Hz | 833 Hz |

| Max. pulse energy | 15 J | 30 J | 30 J |

20 J

50 J |

30 J

60 J |

30 J

60 J 90 J |

30 J |

30 J

70 J 90 J |

30 J

80 J 120 J |

55 J

90 J |

60 J

90 J |

60 J

100 J |

| Min. laser light cable diameter | 100 μm | 300 μm | 400 μm | 200 μm | 400 μm | 300 μm | 600 μm | 400 μm | 600 μm | 300 μm | 400 μm | 600 μm |

| Structural design | ||||||||||||

| Dimensions, basic version (W x H x D) | - | - | - | 980 mm x 1220 mm x 505 mm | 980 mm x 1220 mm x 505 mm | 980 mm x 1220 mm x 505 mm | - | 980 mm x 1220 mm x 505 mm | 980 mm x 1220 mm x 505 mm | - | 1500 mm x 1370 mm x 730 mm | 1500 mm x 1370 mm x 730 mm |

| Dimensions, extended version (W x H x D) | - | - | - | 980 mm x 1220 mm x 715 mm | 980 mm x 1220 mm x 715 mm | 980 mm x 1220 mm x 715 mm | - | 980 mm x 1220 mm x 715 mm | 980 mm x 1220 mm x 715 mm | - | 1500 mm x 1370 mm x 990 mm | 1500 mm x 1370 mm x 990 mm |

| Dimensions (W x H x D) | 485 mm x 700 mm x 800 mm | 485 mm x 700 mm x 800 mm | 485 mm x 700 mm x 800 mm | - | - | - | 980 mm x 1220 mm x 505 mm | - | - | 1500 mm x 1370 mm x 730 mm | - | - |

| Max. number of laser light cables | 3 | 3 | 3 | 6 | 6 | 6 | 3 | 6 | 6 | 6 | 6 | 6 |

| Installation | ||||||||||||

| Protection class (air cooling) | IP22 | IP22 | IP22 | IP22 | IP22 | IP22 | IP22 | IP22 | IP22 | - | - | - |

| Protection class (water cooling) | IP54 | IP54 | IP54 | IP54 | IP54 | IP54 | IP54 | IP54 | IP54 | IP54 | IP54 | IP54 |

| Ambient temperature (water cooling) | 10 °C - 40 °C | 10 °C - 40 °C | 10 °C - 40 °C | 10 °C - 40 °C | 10 °C - 40 °C | 10 °C - 40 °C | 10 °C - 40 °C | 10 °C - 40 °C | 10 °C - 40 °C | 10 °C - 40 °C | 10 °C - 40 °C | 10 °C - 40 °C |

The technical data of all product versions as a download.

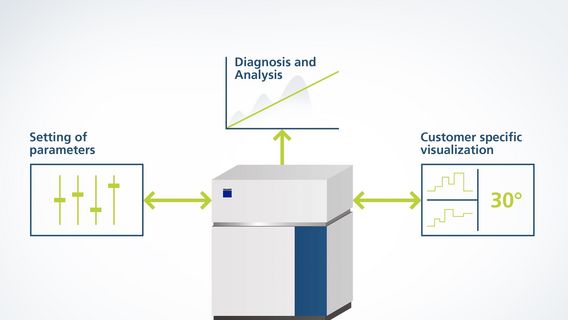

TruControl

TruControl is the control software for your TRUMPF solid-state laser – for quick and simple operation. You can program pulse shapes individually to match your application. The laser power is controlled in real time to ensure maximum reproducibility of your process results. In order to retrace important quality data of your produced parts even years later, the optional DataStore software module records all data relevant to quality.

If external control systems are present, TruControl will communicate with them via all standard interfaces. Inputs are made via the touchscreen of the operating panel or via a panel PC. You can integrate your laser into the network via Ethernet and connect multiple PCs.

With TRUMPF you have the option to flexibly adapt your solid-state laser to your installation and operating situation. This applies, for example, to all beam guidance components and the control. You also have several options for the cooling water supply. Interfaces for different optics are provided right from the start. To save costs, your beam source can also supply several work stations at the same time. The TRUMPF Remote Service helps you to ensure your systems remain available, anywhere and at any time.

There are many options available to you for adapting the laser flexibly to your individual situation. In addition to the laser power and pulse energy, you can also choose the number of fibre outlets up to a total of six. The laser power is regulated for each outlet. The plug & play optical laser cables can be easily connected to different work stations. This allows multiple work stations to operate simultaneously with split laser power or one after the other with full laser power. The modular design enables field repairs to be carried out on site, as well as making the system suitable for retrofitting.

With the laser network, you can network one or more lasers with up to six work stations in each case. In the process, your laser either splits its power to multiple stations, or it supplies them by turns with full power. This allows you to even combine different applications such as welding and cutting with each other. The overall availability of your manufacturing systems therefore increases thanks to simple redundancy concepts.

The TruPulse can be equipped with virtually all standard fieldbus interfaces for control and actuation. The following are also available: real-time interface, parallel digital I/O, interface for process sensor systems, OPC UA software interface and analog input boards.

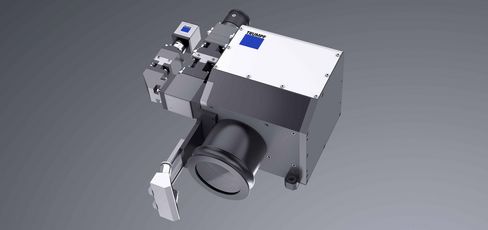

Intelligent optics can be synchronised with your laser via a dedicated interface. This will allow you, for example, to use the CFO focusing optics or PFO scanner optics optimally for your purposes. You can program the processing optics easily using the laser control system. You do not need any additional PCs or control systems.

In the event of a fault, TRUMPF service experts will remotely access your laser via a secure remote connection. In many cases faults can be remedied directly in this way, or the configuration of the laser can be modified in a way that enables you to continue producing until the spare part arrives. This reduces production downtime.

To cool the laser you can choose between water/water or water/air compressor cooling, which means that the TruPulse laser can also be used at high ambient temperatures. If you already have your own cooling circuit in place, you can use it in conjunction with a plate heat exchanger.

The WeldAssist database provides you with welding parameters for various materials and focal diameters. The simplifies the set up of frequently changing laser applications.

Thanks to the TRUMPF sensor system, your production will always be both effective and cost-effective. The sensor products VisionLine, CalibrationLine or integrated pyrometers ensure stable processes by monitoring all the procedures in laser production, thus making a key contribution to your process reliability. Processing continues uninterrupted during the measurement – no interruptions are required, saving you valuable production time.

Image processing

TRUMPF VisionLine image processing detects features on the components and ensures that welding is always performed in the correct location.

Calibration tool

The TRUMPF CalibrationLine tool checks and corrects the focal position and laser power on the workpiece at regular, individually definable intervals.

Lasers and laser systems – with us, the perfect pair. All beam sources are optimally attuned to the requirements of the TRUMPF laser systems. You can choose between numerous variants and options, resulting in a system that is precisely tailored to your task. It is, of course, also possible to integrate our lasers directly into your production lines.

TRUMPF offers you all the components you need for beam guidance from the laser to the workpiece. This also applies for various focusing optics which have proven themselves to be precise and reliable over many years of industrial use. The optics can be easily integrated – both in stand-alone processing stations as well as in complete production lines. The modular structure enables the optics to be continually adapted to the laser types as well as the different processing situations.

Focusing optics

Whether for welding, cutting, ablating, heating up or drilling: with robust focusing optics from TRUMPF you can attain high-quality process results.

Programmable focusing optics

The ideal optics for remote processing

This product range and information may vary depending on the country. Subject to changes to technology, equipment, price and range of accessories. Please get in touch with your local contact person to find out whether the product is available in your country.