The slim frame solution

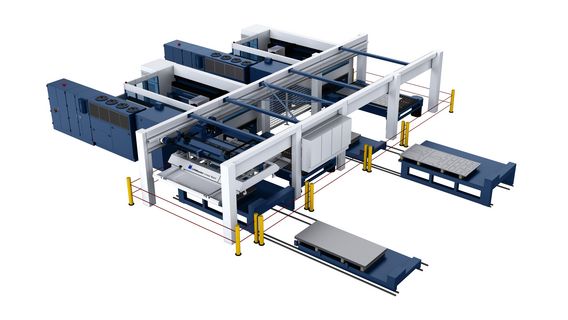

The LiftMaster Linear Basic is the slim solution for automated loading and unloading of sheets. In comparison to the "large" LiftMaster it requires around 15% less installation area. In addition, you can connect several machines to the LiftMaster Linear Basic. This means you can increase the utilisation of up to two machines at a maximum of four tool stations. Cart systems, loading stations and unloading platforms can be integrated with flexibility as required. Storage connection is indirectly possible for the LiftMaster Linear via a cart system.

Automatically load and unload up to two processing machines simultaneously.

Cart systems, loading stations and unloading platforms can be integrated to suit your exact needs.

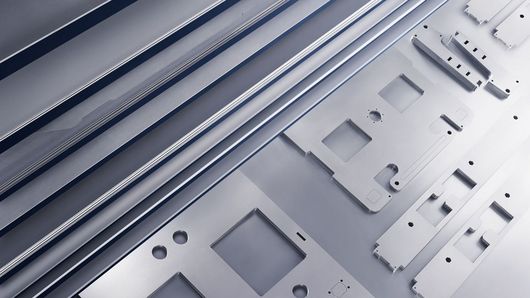

Low-scratch unloading with belt prongs protects your parts.

|

LiftMaster Linear Basic

|

|

|---|---|

| Loading | |

| Maximum sheet size | 3000 mm x 1500 mm |

| Minimum sheet size | 1000 mm x 1000 mm |

| Maximum sheet thickness | 25 mm |

| Maximum sheet weight | 900 kg |

| Unloading | |

| Maximum sheet size | 3000 mm x 1500 mm |

| Minimum sheet size | 150 mm x 150 mm |

| Maximum sheet thickness | 25 mm |

| Maximum sheet weight | 900 kg |

The technical data of all product versions as a download.

The unloading rake takes the finished, processed sheet from the pallet changer and sets it down in the unloading area. The suction frame is fitted with individually controllable suction cups that pick up the unprocessed sheets from the loading area, and set them down onto the pallet changer.

So-called belt prongs enable the unloading of parts with a high level of positioning accuracy and minimal scratching.

With the LiftMaster Linear Basic you can load and unload up to two processing machines simultaneously.

TruLaser 3030 with LiftMaster Linear Basic

This product range and information may vary depending on the country. Subject to changes to technology, equipment, price and range of accessories. Please get in touch with your local contact person to find out whether the product is available in your country.