Thanks to the many interfaces, such as the OPC UA, the TruMark 7050 can easily be integrated into complex processing environments.

Benefit from the advantages of the next generation of high-performance multi-function lasers

More power, more speed, more flexibility, and more applications: the requirements of deep laser engraving, fast ablation, large scale surface structuring, and cleaning are continuously being improved. The TruMark 7050 was designed as a multi-functional tool and is a turnkey solution that is easy to operate and integrate. The device offers a new performance level in marking and thus a range of new applications. The TruMark 7050 provides an excellent beam quality that is essential for providing optimum results in every sector. The laser system offers the perfect combination of high power, high pulse repetition frequency and an adjustable pulse duration.

A laser source with an average power of 200 W and a peak power of more than 10 kW achieves the highest processing speeds and short cycle times.

The highest productivity requirements are met by the high level of average power and high pulse repetition frequency.

The TruTops Mark 3D software comprises a comprehensive 3D-CAD editor and depicts components and marking content or material processing steps in 3D.

The many interfaces, removable connecting cable and 19-inch plug-in units ensure that the laser is easily and quickly integrated into any production line.

Modern production technologies and powerful optical components make the laser a high-end industrial device.

A consistent laser power that is checked by the fast internal power measuring system is essential for ensuring stable marking and processing quality.

Once the safety circuit is closed, the laser is available within 50 ms. Unlimited clock cycles ensure highly efficient production.

Deep engraving

In the automotive industry, the TruMark 7050 generates high-quality deep engraving, such as the vehicle identification number (VIN) on the automobile body.

Spot welding

E-mobility applications require the connection of the same and different types of materials (including copper with stainless steel or brass, aluminium with brass) - using the TruMark 7050 this can be achieved in a very short time

Structuring

The TruMark 7050 is perfect for roughening surfaces to prepare them for subsequent bonding processes.

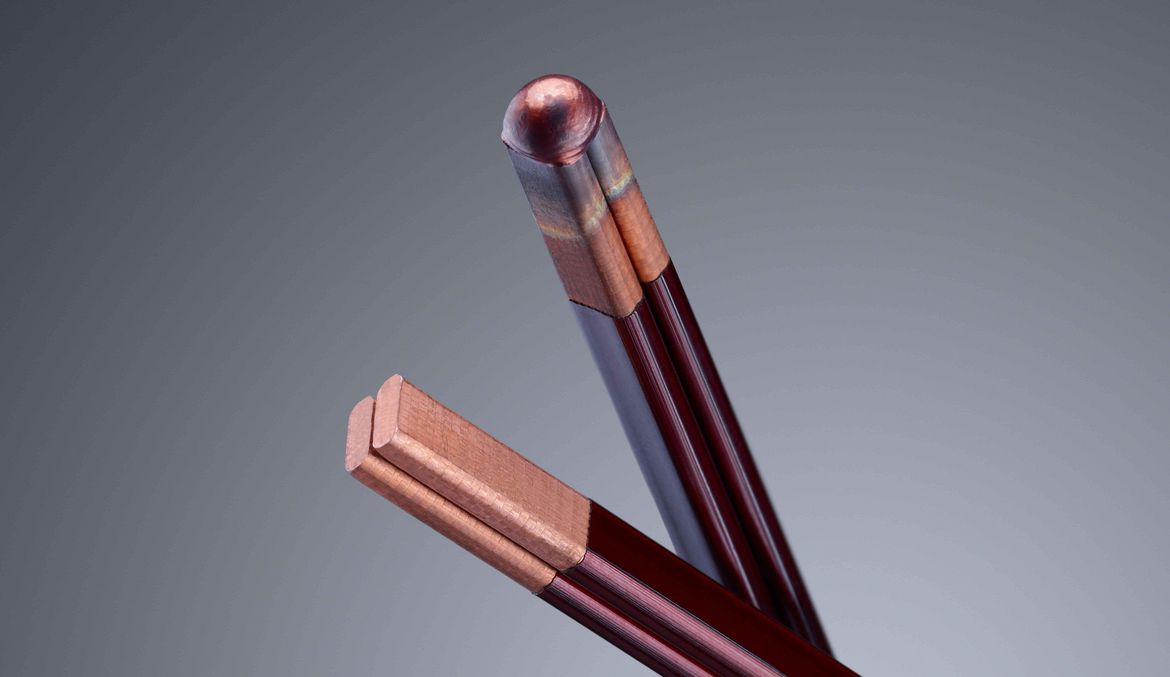

Hairpin stripping of copper chamfers

In the context of manufacturing electric motors, the TruMark 7050 is best used for the hairpin stripping of copper cables. This process removes the plastic sheathing.

|

TruMark 7050 (L042)

|

TruMark 7050 (L051)

|

|

|---|---|---|

| Laser parameters | ||

| Beam quality (M²) | < 1.6 | < 6 |

| Fibre type | Z type | M type |

| Wavelength | 1062 nm ± 3 nm | 1062 nm ± 3 nm |

| Pulse sequence frequency | 1 kHz - 4000 kHz | 1 kHz - 4000 kHz |

| Minimum focal diameter | 40 μm (mit f=160 FS RF Objektiv) | 150 μm (mit f=160 FS RF Objektiv) |

| Maximum text field size | 285 mm x 285 mm | 285 mm x 285 mm |

| Structural design | ||

| Dimensions of laser head (W x H x D) | 144 mm x 161 mm x 574 mm | 144 mm x 161 mm x 574 mm |

| Dimensions of supply unit (W x H x D) | 446 mm x 222 mm x 495 mm | 446 mm x 222 mm x 495 mm |

| Installation | ||

| Ambient temperature | 15 °C - 40 °C | 15 °C - 40 °C |

The technical data of all product versions as a download.

Expand your available marking field to 285 x 285 mm2 for increased flexibility when it comes to the component size.

A number of fieldbus systems such as Profibus, Profinet, EtherCAT and EthernetIP will assist you with the integration.

With our NAVIGATOR software module, even operators without prior experience can quickly find the right laser settings for different raw materials.

For higher requirements in terms of spray and dust protection according to IP 54, a housing is available with integrated 19-inch supply unit and control computer.

The operating package consists of a monitor, a keyboard and a mouse to operate the marking laser.

With the optional emissions exhaust system (which is also available externally), you can always work safely with the TruMark 7050.

In the event of a fault, TRUMPF service experts will remotely access your laser via a secure remote connection. In many cases the fault can be remedied directly in this way, or the configuration of the laser can be modified in a way that permits you to continue manufacturing until the spare part arrives.

This product range and information may vary depending on the country. Subject to changes to technology, equipment, price and range of accessories. Please get in touch with your local contact person to find out whether the product is available in your country.

Find your perfect marking laser now

Use the TruMark product finder to discover which marking laser is best suited to your application!