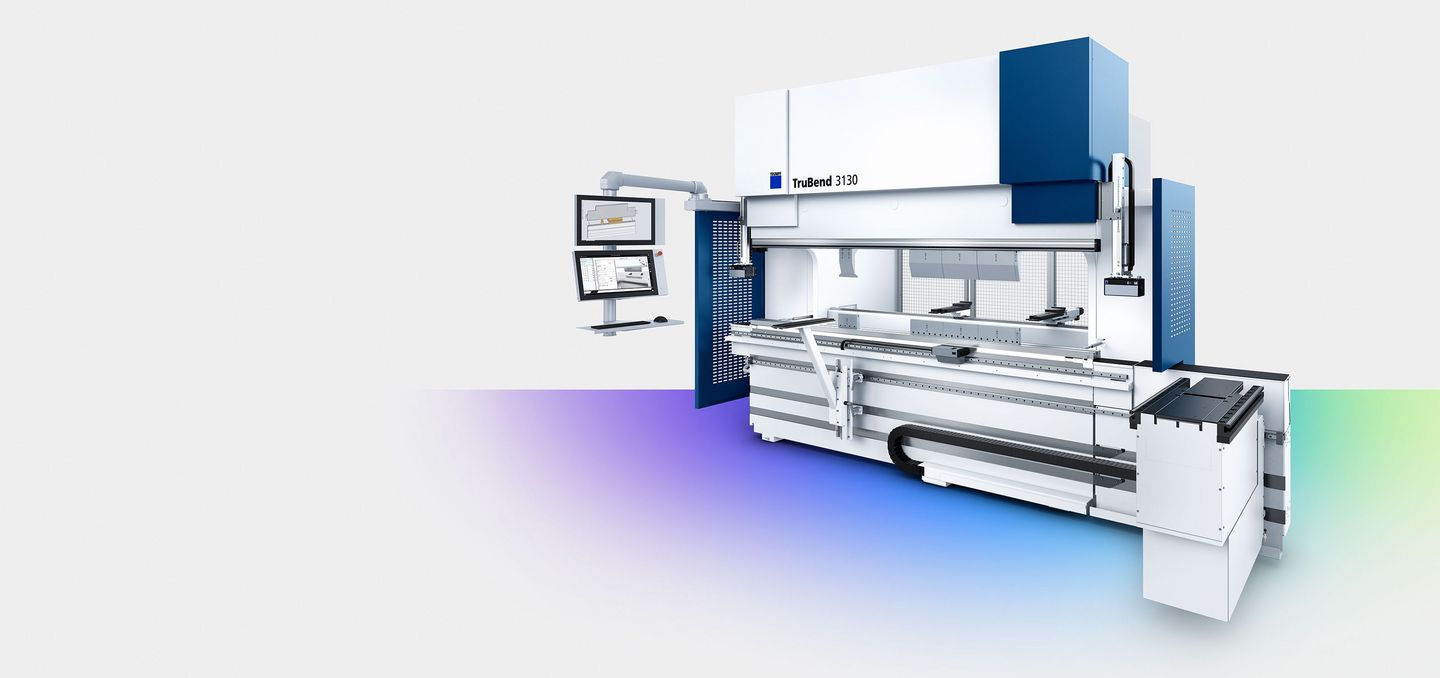

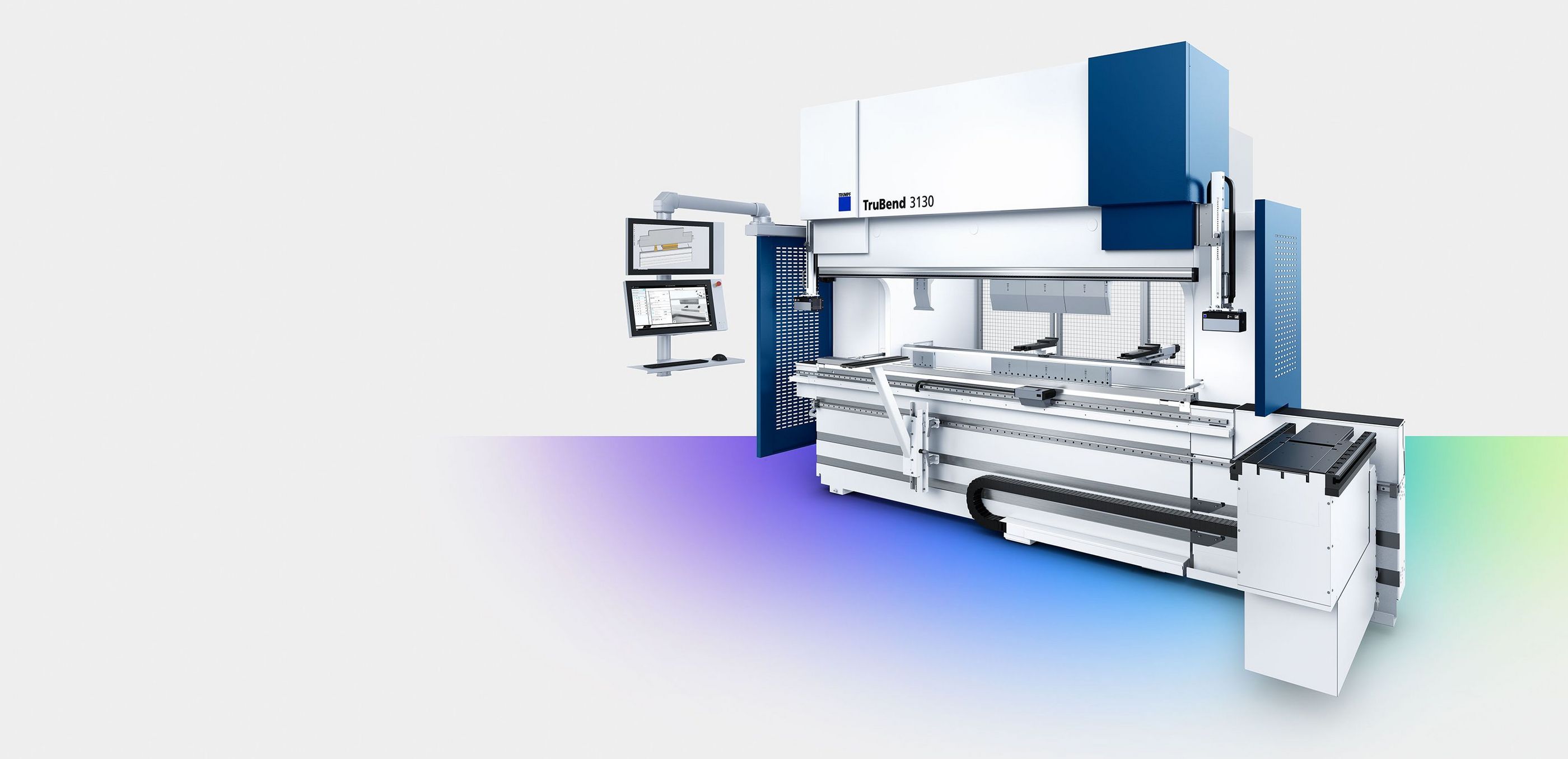

The multipurpose powerhouse – economical, precise, future-proof

If your daily work involves limited budgets, where every detail has to be right and processes must be stable, you need a machine that delivers exactly that. The TruBend Series 3000 has been developed to support you in your daily challenges – even when handling complex and demanding bending parts. The machine is a reliable all-rounder, delivering continuously stable performance. You benefit from precise angles, consistent component quality, and solutions that noticeably reduce your production workload. Because big results are created by small teams

To ensure your investment delivers returns, you benefit from selected premium features at an attractive price, maximising cost-effectiveness and enhancing competitiveness.

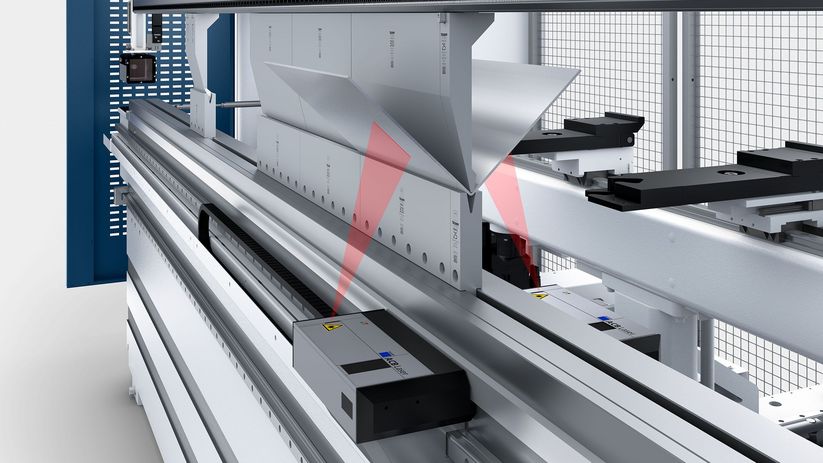

Because ±0.3° makes all the difference, the ACB laser angle measuring system automatically ensures precise angles.

So that no component has to wait, you can create bending programs offline with TRUMPF's TecZone Bend software, while the machine continues production in parallel.

To make handling heavy parts easier, the new bending aid with a 150 kg carrying capacity significantly reduces strain and enables more productive work.

Because idle states are not an option, we support you with TRUMPF bending tools, training and technical support.

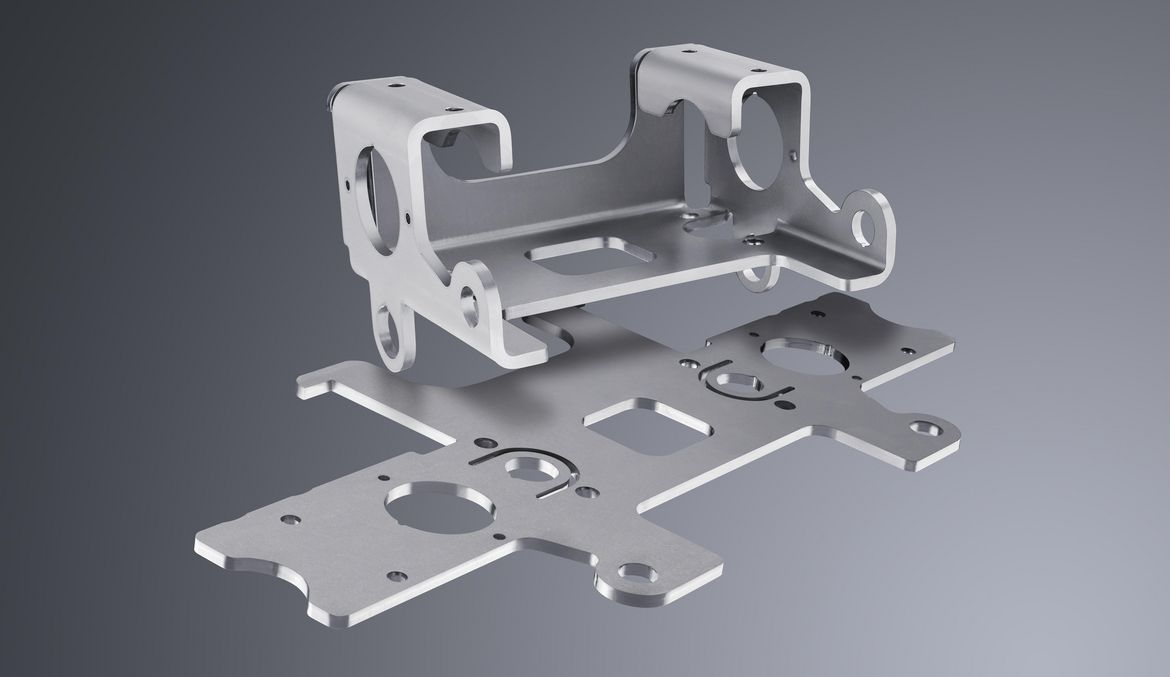

Component with different bends

The TruBend Series 3000 is so flexible that a wide variety of tasks can be implemented without any problems.

Long profiles

Produce long profiles with ease using TruBend Series 3000 machines, thanks to additional clip-on gauge fingers.

The highest level of flexibility in different sheet thicknesses

Process parts with the most varied sheet thicknesses in next to no time on the TruBend Series 3000 machines.

Selected premium features make working with the TruBend Series 3000 even more precise, ergonomic and productive. Here, you will find a selection of the available equipment for the bending machines.

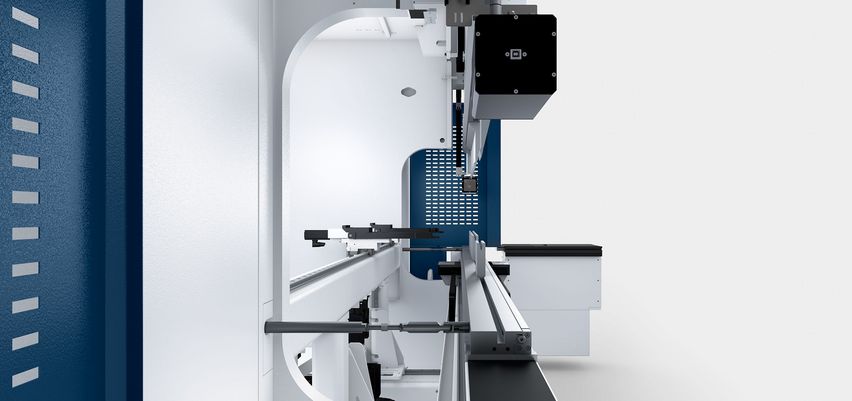

The ACB Laser is a non-contact, optical system for angle measurement. A laser projects a line onto the sheet; a camera detects the angle. For this purpose, the front and rear measuring units are moved automatically to the correct position or CNC-controlled. Four different measuring methods (ACB Speed, ACB Smart, Identify and Copy Plunging Depth) increase the area of application and productivity. Your components receive consistent, precise angles with an accuracy of ± 0.3° across a wide measuring range from 30° to 150°. Even the first part is a good part, regardless of the material.

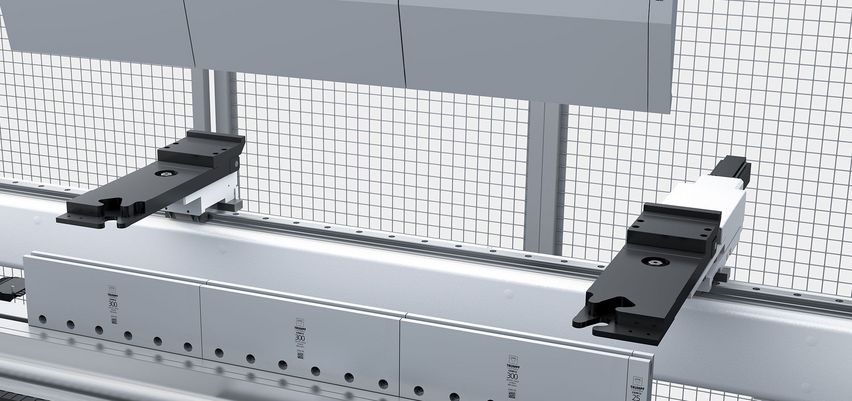

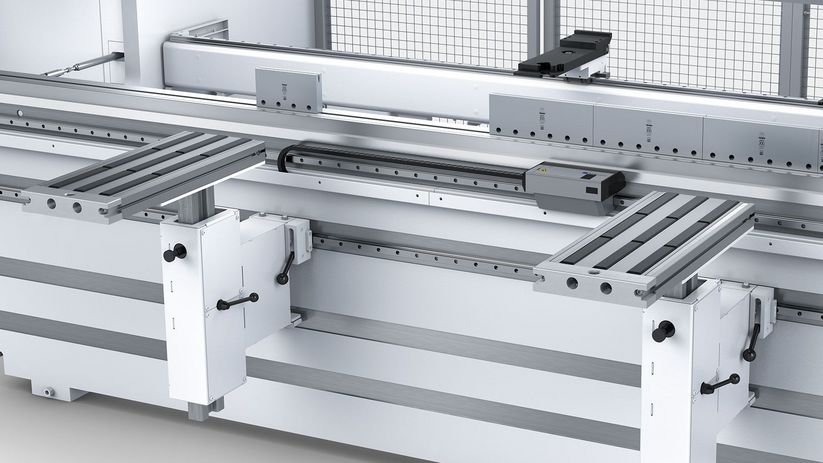

The backgauge on the TruBend Series 3000 is equipped with four axes as standard and can be scaled to five axes. In combination with the angled stop, this allows you to cover an even wider range of components. In addition, the 5-axis backgauge allows the right-hand gauge finger to be moved in the X direction (max. traverse path ±75 mm). With up to three additional gauge fingers available, even long profiles can be manufactured with precision. The lateral stop (clamp) further increases productivity and user-friendliness.

The practical bending aids with plastic pad provide valuable assistance. Each machine can be equipped with up to two bending aids, each boasting a high carrying capacity of 150 kg. They support and relieve the strain on operators when bending heavy or large parts, making handling much easier. This also prevents the back-bend effect in the case of thin sheets with large flange lengths. User-friendliness is enhanced by the CNC-controlled height axis and automatic adjustments for die height and part geometry.

Two types of support bracket are available: standard support bracket 70 with a load capacity of up to 70 kg or, optionally, support bracket 100 with a load capacity of up to 100 kg and additional positioning options in the X direction. Both variants are infinitely adjustable in height and mounted on guide rails to fix them anywhere.

You can expand the support arm system by adding a second monitor above the main monitor. The additional monitor on the machine control supports paperless production and is used for further visualisation of documents (e.g., images, PDFs) or for displaying TRUMPF's TecZone Bend software, for example. Both monitors can be swivelled, and are operated using a mouse and keyboard.

Seamless integration of many TRUMPF machines into your own software environment is very easy. We have the right solution for every combination, whether it be integration into Oseon or a connection to monitoring and analysis tools. A connection to third-party software systems is also possible with our interfaces based on the OPC UA standard.

TruTops Boost

Program your bending machines intelligently using TruTops Boost, the all-in-one solution for 3D design. Numerous automated processes save you time-consuming routine processes. You also profit from a comprehensive ruleset with the bundled technical expertise of TRUMPF.

TecZone Bend

Program faster than ever before: with TecZone Bend you can combine bend programming in the office with shop floor programming at the TruBend bending machine. A program suggestion is automatically created in a few seconds based on 2D and 3D data – including NC program.

Software

The software portfolio from TRUMPF optimises your entire production process – from the customer query to delivery of the finished part. TRUMPF combines the software intelligently with machines and services to create customised Industry 4.0 solutions for your Smart Factory.

You can choose between more than 150 upper and lower tool types for your personal range. You can order tools individually or as a set.

For tools up to 300 mm long, lightweight tools with a weight saving of more than 30% are equipped with the Safety-Click as standard. This reduces the setup time and relieves the strain on the operator.

During the processing of galvanised sheets, even after just a few bends, there may be zinc deposits on the die, resulting in cold welding. This can lead to imprints on the component and imprecision. This can be avoided with the coated LASERdur ZN TRUMPF bending tools. They combine a high level of surface hardness with excellent sliding properties, are corrosion-resistant and do not require cleaning.

For specific requirements, TRUMPF will develop your own personal tool solution. To guarantee the quality of your parts, we test the tools in advance with your specific material and create initial sample parts.

This product range and information may vary depending on the country. Subject to changes to technology, equipment, price and range of accessories. Please get in touch with your local contact person to find out whether the product is available in your country.