When size matters: heavy-duty large format bending with high precision and full flexibility

If you need a special machine that does not instantly reach its performance limits even when performing a wide variety of tasks and meeting special requirements, and is easy to load even with large parts, then the TruBend Series 8000 is made for you. This special machine is well equipped for any heavy-duty task and easy to operate. The powerful press force can handle even the toughest challenges without compromising on precision. The options for large and heavy components have never been greater, thanks in part to the available tandem design. Our underfloor machines are an ideal addition for even greater bending lengths and tonnages.

Because premium performance knows no bounds.

The machine can be used flexibly for different applications, which means that numerous customisation options are available to give you your own individual TruBend Series 8000.

A large-format machine needs to be able to handle large items, which is why there are floor-mounted versions with weights of up to 400 t and lengths of up to 6.10 m, or weights of up to 600 t and lengths of up to 4.40 m.

No task is too difficult, as the crowning and hydraulic upper and lower tool clamps can withstand up to 6,000 kN/m.

To ensure that loading and handling do not cause any problems, the machine has a large throat depth and a wide selection of equipment options that facilitate processing.

Your investment in TRUMPF is valuable in the long term, which is why we offer not only innovative machines but also excellent service and a wide range of additional services.

High nesting, simple unthreading

With an installation height of 880 mm, there is also room for workpieces with large box heights. Machine operators can bend and unthread the workpieces easily. Another advantage is that all TRUMPF standard tools are compatible without the need for adapters, thanks to the 700 mm stroke.

Bending long, thin parts

The TruBend Series 8000 bending machines, with their extensive bending length of 4.40 metres, are well-suited to large, heavy components and longer, thinner ones.

Save setup time

Station bending is practical. You have the flexibility to use different upper and lower tools side by side, allowing you to process a range of parts and bends without the need for frequent retooling.

Powerhouse

With a press force of up to 600 t/m, the new generation machines are exceptionally well-suited for bending thick and short sheet metal.

|

TruBend 8230 (bending length 4420 mm)

Compare product

|

TruBend 8320 (bending length 3230 mm)

Compare product

|

TruBend 8320 (bending length 6120 mm)

Compare product

|

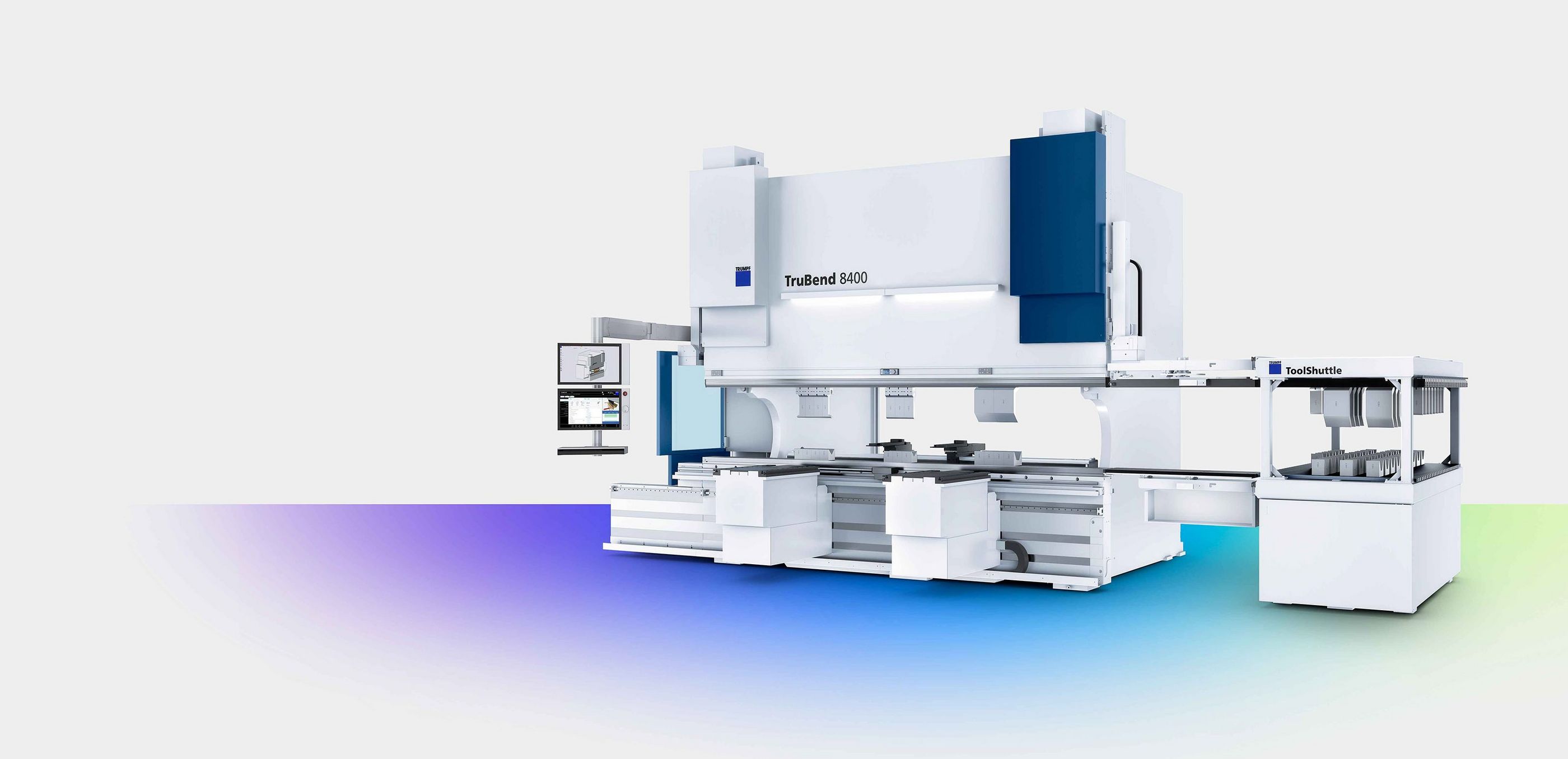

TruBend 8400 (bending length 4420 mm)

Compare product

|

TruBend 8400 (bending length 6120 mm)

Compare product

|

TruBend 8600 (bending length 4420 mm)

Compare product

|

TruBend 8600 (bending length 6120 mm)

Compare product

|

TruBend 8800 (bending length 6120 mm)

Compare product

|

TruBend 8800 (bending length 7050 mm)

Compare product

|

TruBend 8800 (bending length 8050 mm)

Compare product

|

TruBend 81000 (bending length 7050 mm)

Compare product

|

TruBend 81000 (bending length 8050 mm)

Compare product

|

|

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Press force | 2300 kN | 3200 kN | 3200 kN | 4000 kN | 4000 kN | 6000 kN | 6000 kN | 8000 kN | 8000 kN | 8000 kN | 10000 kN | 10000 kN |

| Bending length | 4420 mm | 3230 mm | 6120 mm | 4420 mm | 6120 mm | 4420 mm | 6120 mm | 6120 mm | 7050 mm | 8050 mm | 7050 mm | 8050 mm |

| Width between columns | 3680 mm | 2510 mm | 5090 mm | 3680 mm | 5090 mm | 3680 mm | 5090 mm | 5100 mm | 6050 mm | 7050 mm | 6050 mm | 7050 mm |

| Max. distance between press beam and table | - | 1000 mm | - | 1000 mm | - | 1000 mm | 1000 mm | - | - | - | - | - |

| Usable open height | 880 mm | 880 mm | 880 mm | 880 mm | 880 mm | 880 mm | 880 mm | 675 mm 1 | 675 mm 1 | 675 mm 1 | 675 mm 1 | 675 mm 1 |

| Throat depth | 620 mm | 620 mm | 620 mm | 620 mm | 620 mm | 620 mm | 620 mm | 420 mm 1 | 420 mm 1 | 420 mm 1 | 420 mm 1 | 420 mm 1 |

| User interface | T-8000 S multi-touch control | T-8000 S multi-touch control | T-8000 S multi-touch control | T-8000 S multi-touch control | T-8000 S multi-touch control | T-8000 S multi-touch control | T-8000 S multi-touch control | T-8000 S multi-touch control | T-8000 S multi-touch control | T-8000 S multi-touch control | T-8000 S multi-touch control | T-8000 S multi-touch control |

| Maximum speed Y axis, operation | 10 mm/s | 10 mm/s | 10 mm/s | 10 mm/s | 10 mm/s | 10 mm/s | 10 mm/s | 10 mm/s | 10 mm/s | 10 mm/s | 8 mm/s | 8 mm/s |

| Dimensions, weights | ||||||||||||

| Length | 5318 mm | 4188 mm | 7090 mm | 5398 mm | 7103 mm | 5458 mm | 7165 mm | 7180 mm | 8150 mm | 9150 mm | 8150 mm | 9150 mm |

| Width | 2830 mm | 2830 mm | 2830 mm | 2830 mm | 2830 mm | 2830 mm | 2880 mm | 2980 mm 2 | 2980 mm 2 | 2980 mm 2 | 2980 mm 2 | 2980 mm 2 |

| Height | 3970 mm | 3970 mm | 3970 mm | 3970 mm | 3970 mm | 3970 mm | 3995 mm | 4570 mm 2 | 4570 mm 2 | 4770 mm 2 | 4750 mm 2 | 4750 mm 2 |

| Weight | 25000 kg | 26000 kg | 40000 kg | 34000 kg | 45000 kg | 45000 kg | 51000 kg | 70000 kg | 74000 kg 2 | 82000 kg 2 | 93000 kg 2 | 98000 kg 2 |

|

TruBend 8230 (bending length 4420 mm)

|

TruBend 8320 (bending length 3230 mm)

|

TruBend 8320 (bending length 6120 mm)

|

TruBend 8400 (bending length 4420 mm)

|

TruBend 8400 (bending length 6120 mm)

|

TruBend 8600 (bending length 4420 mm)

|

TruBend 8600 (bending length 6120 mm)

|

TruBend 8800 (bending length 6120 mm)

|

TruBend 8800 (bending length 7050 mm)

|

TruBend 8800 (bending length 8050 mm)

|

TruBend 81000 (bending length 7050 mm)

|

TruBend 81000 (bending length 8050 mm)

|

|

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Press force | 2300 kN | 3200 kN | 3200 kN | 4000 kN | 4000 kN | 6000 kN | 6000 kN | 8000 kN | 8000 kN | 8000 kN | 10000 kN | 10000 kN |

| Bending length | 4420 mm | 3230 mm | 6120 mm | 4420 mm | 6120 mm | 4420 mm | 6120 mm | 6120 mm | 7050 mm | 8050 mm | 7050 mm | 8050 mm |

| Width between columns | 3680 mm | 2510 mm | 5090 mm | 3680 mm | 5090 mm | 3680 mm | 5090 mm | 5100 mm | 6050 mm | 7050 mm | 6050 mm | 7050 mm |

| Max. distance between press beam and table | - | 1000 mm | - | 1000 mm | - | 1000 mm | 1000 mm | - | - | - | - | - |

| Usable open height | 880 mm | 880 mm | 880 mm | 880 mm | 880 mm | 880 mm | 880 mm | 675 mm 1 | 675 mm 1 | 675 mm 1 | 675 mm 1 | 675 mm 1 |

| Throat depth | 620 mm | 620 mm | 620 mm | 620 mm | 620 mm | 620 mm | 620 mm | 420 mm 1 | 420 mm 1 | 420 mm 1 | 420 mm 1 | 420 mm 1 |

| User interface | T-8000 S multi-touch control | T-8000 S multi-touch control | T-8000 S multi-touch control | T-8000 S multi-touch control | T-8000 S multi-touch control | T-8000 S multi-touch control | T-8000 S multi-touch control | T-8000 S multi-touch control | T-8000 S multi-touch control | T-8000 S multi-touch control | T-8000 S multi-touch control | T-8000 S multi-touch control |

| Maximum speed Y axis, operation | 10 mm/s | 10 mm/s | 10 mm/s | 10 mm/s | 10 mm/s | 10 mm/s | 10 mm/s | 10 mm/s | 10 mm/s | 10 mm/s | 8 mm/s | 8 mm/s |

| Dimensions, weights | ||||||||||||

| Length | 5318 mm | 4188 mm | 7090 mm | 5398 mm | 7103 mm | 5458 mm | 7165 mm | 7180 mm | 8150 mm | 9150 mm | 8150 mm | 9150 mm |

| Width | 2830 mm | 2830 mm | 2830 mm | 2830 mm | 2830 mm | 2830 mm | 2880 mm | 2980 mm 2 | 2980 mm 2 | 2980 mm 2 | 2980 mm 2 | 2980 mm 2 |

| Height | 3970 mm | 3970 mm | 3970 mm | 3970 mm | 3970 mm | 3970 mm | 3995 mm | 4570 mm 2 | 4570 mm 2 | 4770 mm 2 | 4750 mm 2 | 4750 mm 2 |

| Weight | 25000 kg | 26000 kg | 40000 kg | 34000 kg | 45000 kg | 45000 kg | 51000 kg | 70000 kg | 74000 kg 2 | 82000 kg 2 | 93000 kg 2 | 98000 kg 2 |

A range of functions make bending with the TruBend Series 8000 even safer, easier, more ergonomic and more productive.

Flexibility and precision

Sensor disks integrated in the upper tool measure and correct every angle so that you always get accurate results. The user-friendly ACB (Automatically Controlled Bending) wireless system automatically detects the sensor position, facilitating wireless communication between the tool and control.

ACB Laser is an optical system for angle measurement. Without requiring any contact, the laser projects a line onto the sheet, and a camera detects the angle. This ensures that you get accurate results right from the very first component. For the angle measurement, 2 measuring units automatically move to the correct position without any operator intervention.

Up to 6 CNC-controlled backgauge axes position your workpieces precisely and securely so that you can bend accurately along the entire length, even with deep flanges. Optionally, the backgauges are also available in an extremely robust heavy-duty version with a traverse path of up to 1,000 mm.

Automatic crowning works precisely down to the last detail. At a distance of 250 mm, you can adjust the crowning curve precisely to your bending task as required. The crowning can be loaded up to 6,000 kN/m, so that you always get exactly the required press force.

The lower tool displacement enables you to perform two bending operations with one tool. Specifically, this means that you can increase your part variety, while cutting setup time and investment costs. In addition, special applications such as folding can also be performed effectively with the lower tool displacement.

Energy efficiency

With its On-Demand Drive, the new TruBend Series 8000 also scores highly in terms of sustainability. The revolution speed of the motor is automatically adapted to the movement of the press beam. This achieves energy savings of up to 26% while maintaining extremely quiet bending.

Material handling

Managing heavy parts becomes more convenient thanks to the infinitely height-adjustable support brackets. The sturdy support brackets can be loaded individually with weights of up to 300 kg and come with various support options.

The bending aid with automatic height adjustment provides support to bending personnel, particularly when working with heavy or large-format parts. The heavy-duty version can withstand loads of up to 300 kg.

Operator ergonomics

The handy MobileControl and MobileControl Pro operating units are fixed to a communications rail in the press beam along the entire bending length. This allows you to have essential functions within easy reach, without moving around constantly.

An additional screen on the machine control helps to keen operation simple. It can help you to perform shop floor programming while simultaneously carrying out production tasks. The user-friendly display of information on the monitors supports paperless manufacturing.

The new control and navigation of the TruBend Series 8000 combines the advantages of modern multi-touch technology with industrial-grade robustness. This enables you to operate your bending machine as easily and intuitively as a tablet or smartphone – and realise almost any application with ease.

Additional LEDs illuminate the operating area as effectively as possible, ensuring safer operation and better working conditions. At the same time, they prevent heat generation that can be disruptive to the operating personnel.

Setup with luminous display – the LED bar in the upper tool clamp clearly indicates the precise locations where the tool stations should be set up. It also provides a visual display of the current machine status and indicates which tool station will be used for the next bend. The illuminated signs reduce unnecessary trips to the control panel.

The bending line laser allows you to accurately align the parts for bending. For this purpose, the system projects a laser line onto the sheet metal, which serves as a visual aid for the operator during bending. The main benefits of this are reduced rejects and increased productivity. The bending line laser also enables bending on a scribed line, i.e. bending without the support of the backgauge system – for extra working space.

TruTops Boost

Program your bending machine using Tops Boost, the all-in-one solution – from design to the finished NC program. Routine tasks that take up a lot of time can be automated with the click of a button, saving you valuable working time. You also profit from comprehensive rule sets that incorporate TRUMPF's collective technical expertise.

TecZone Bend

Program faster than ever before: with TecZone Bend you can combine bend programming in the office with shop floor programming at the TruBend bending machine. A program suggestion is automatically created in a few seconds based on 2D and 3D data – including NC program.

Software

The software portfolio from TRUMPF optimises your entire production process – from the customer query to delivery of the finished part. TRUMPF combines the software intelligently with machines and services to create customised Industry 4.0 solutions for your smart factory.

ToolShuttle, the practical tool magazine, stands directly next to your TruBend Series 8000 machine. Tools are simply pushed in and out of the machine during setup, which is particularly convenient for heavy tools and also saves time. The ToolShuttle has space for nearly 60 m of tools and ensures everything is organised.

You can choose between more than 150 upper and lower tool types for your personal range. You can order tools individually or as a set.

These bending tools with consistent die width use an innovative die geometry to combine multiple functions in one design. This makes bending easier, faster and more flexible than ever. The special geometry simultaneously ensures a narrower impression width on the sheet, optimal bending foil effect, and a shorter minimum flange length.

For specific requirements, TRUMPF will develop your own personal tool solution. To guarantee the quality of your parts, we test the tools in advance with your specific material and create initial sample parts. This allows you to remain as flexible as possible in the production of components, or even cover additional applications.

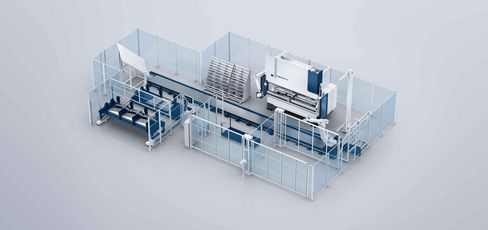

Automation solution with Starmatik

With the robot on a movable transverse rail, the TruBend 8000 can bend sheets up to eight metres in length with a maximum weight of 220 kilograms fully automatically. The configuration is tailored to your needs. If required, you can add a storage connection, centering station, gripper and tool change along with a regripping station and other sheet processing processes, such as joining or thermoforming. The entire solution can be programmed offline.

This product range and information may vary depending on the country. Subject to changes to technology, equipment, price and range of accessories. Please get in touch with your local contact person to find out whether the product is available in your country.

- durch Option vergrößerbar

- können mit Optionen abweichen