NEW! TruBend Series 1000

Cost-effective introduction to the TRUMPF bending machine world. The press brakes impress with simple and reliable operation at high levels of precision and appropriate safety standards.

Innovative ideas drive forward bending – and therefore your company, too. Modern TruBend bending machines from TRUMPF impress with functions that save resources, make operation easier and ensure precise quality – from the very first part. Whether it’s laser-measured angles, energy-saving hydraulics or fully automatic tool changes – find out more about our press brake and how you can make your bending production even more successful and boost your sheet metal factory.

The I-Axis is a unique TRUMPF press brake function in which the bottom die can shift horizontally what gives you more flexibility in the whole bending process. As a result, the number of setups and parts are significantly reduced moreover you are able to use different height tooling in one single setup (e.g. multiple V openings may be used). This leads to a much higher productivity and output.

Numerous factors influence angle precision when bending, for example fluctuating strengths in the material or spring back. The solution: automatic angle measuring systems from TRUMPF called ACB Wireless or ACB Laser. The ACB systems’ sensors record in real-time, the actual angle and spring back and control the press beam so that the desired angle is bent – quickly and precisely. The two ACB Laser and ACB Wireless systems complement one another; one system may be more appropriate than the other depending on the application.

We have a wide variety of adapters to enable non TRUMPF tools to be used on our machines. Nevertheless, at TRUMPF, we focus on customer-specific consultancy and the production of highly precise, durable tools. We are developing solutions to suit your application cases, including for complex requirements. What's more, we offer a comprehensive range of standard tools as well as special tooling solutions. We are also able to provide electronic tool data to import directly into the machine control.

At TRUMPF we offer you a variety of software solutions which are tailored for your needs and your press brake like TruTops Bend or TecZone Bend. TecZone Bend, the latest bending software combining bend programming in the office with shop floor programming at the TruBend bending machine as well as offline programming. All TRUMPF software is easy to use and have an intuitive operating concept.

You can set up your press brake automatically for each new program with the automatic ToolMaster tool changer system. This is a priceless benefit, particularly for small lot sizes, as you save a great deal of time and effort in comparison to the manual procedure.

The next step would be one of the bending cells which offers you a fully automated bending solution. You have maximum freedom in the design of the material flow using conveyor belts and pallet conveyors. Its the next step to your own smart factory!

Skilled operators are hard to find nowadays. Our intuitive operation and programming with multiple options like the part indicator, ACB System, tool indicator, touchpoint control, bending aid, MobileControl makes the bending process simple and is easy to learn.

Most bending parts are produced using air bending, bottom bending, or folding and hemming. These methods and processes all work in the same way: a punch presses the workpiece into the lower tool of the die. That is why the bending machines which carry out these methods and processes are called press brakes. TRUMPF press brakes are available in a range of configurations and sizes to suit all applications.

Innovative ideas drive forward bending, and therefore your company's success, too. All press brakes from TRUMPF have a variety freely selectable options which saves resources, simplify operation and guarantee precision quality.

We have a large portfolio of press brakes which can fit every budget. Please contact us directly for any price information, we are happy to help!

The I-Axis is a unique TRUMPF press brake function in which the bottom die can shift horizontally what gives you more flexibility in the whole bending process. As a result, the number of setups and parts are significantly reduced moreover you are able to use different height tooling in one single setup (e.g. multiple V openings may be used). This leads to a much higher productivity and output.

If you want to know more about our press brake solutions for your specific sheetmetal process, send us an email.

Cost-effective introduction to the TRUMPF bending machine world. The press brakes impress with simple and reliable operation at high levels of precision and appropriate safety standards.

The most cost-efficient press brake – a combination of high quality with simple operation and an attractive price-performance ratio.

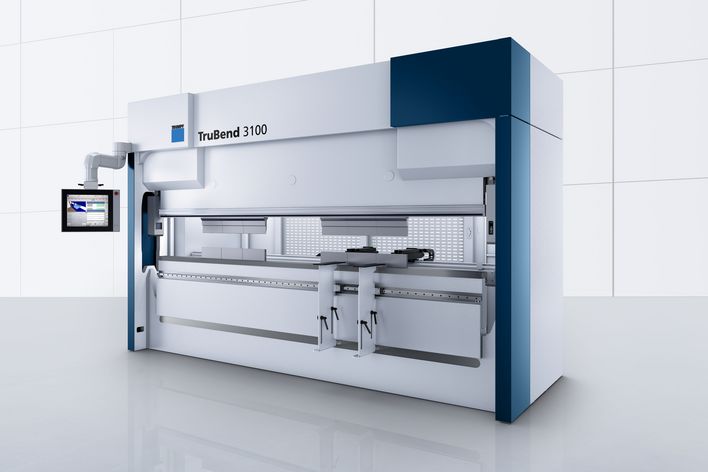

The productive all-round press brake machine – with its high number of benefits and functions during programming, setup and operation, you achieve unrivalled productivity during production.

The ergonomic high-speed press brake – it bends small and medium-sized parts under top work conditions in a space-saving and highly productive manner.

The flexible large-format bending machine – with up to 1,000 t of press force, it bends small, large, or extra-large parts powerfully and precisely.

Productive universal bending cell: the ideal solution for anyone who values productive and flexible automation for the widest possible range of bending parts. Quality remains consistently high.

The innovative high-speed bending cell – you can bend small parts dynamically and extremely cost-efficiently with the quickest system in the world.

The panel bending team player reduces the operator’s workload with semi-automatic top-class technology. Even on intricate tasks, it delivers first-class results and efficiently bends small lot sizes.

The fully automatic bending center is unbeatable when it comes to high-level productivity. With its constancy and technical versatility, it reduces the workload of your entire team: its rotary part manipulator handles sheets perfectly and allows you to bend them in record time.

At TRUMPF, we focus on customer-specific consultancy and the production of highly precise, durable tools. Because only the original can guarantee this, we have been producing our own bending tools for more than 20 years – in top quality and with the broadest range of tools on the market.

If you want to know more about our press brake solutions for your specific sheetmetal process, send us an email.