If Jürgen Bickel thinks about panel bending, then he is reminded of his beginnings as a building fitter in 1983. He launched his company with a TRUMPF copy nibbler, a pre-owned guillotine shears and a manual panel bending machine. In December of 2014, panel bending had caught up with Bickel once again. He was the world’s first customer to obtain a TruBend Center built by TRUMPF. Decisive for Bickel Blechtechnik are the system’s many options for use. And ultimately the company had long since parted ways with low-margin, mass production orders. Jürgen Bickel and his team are making good marks again with customized solutions realized as prototypes and in series production.

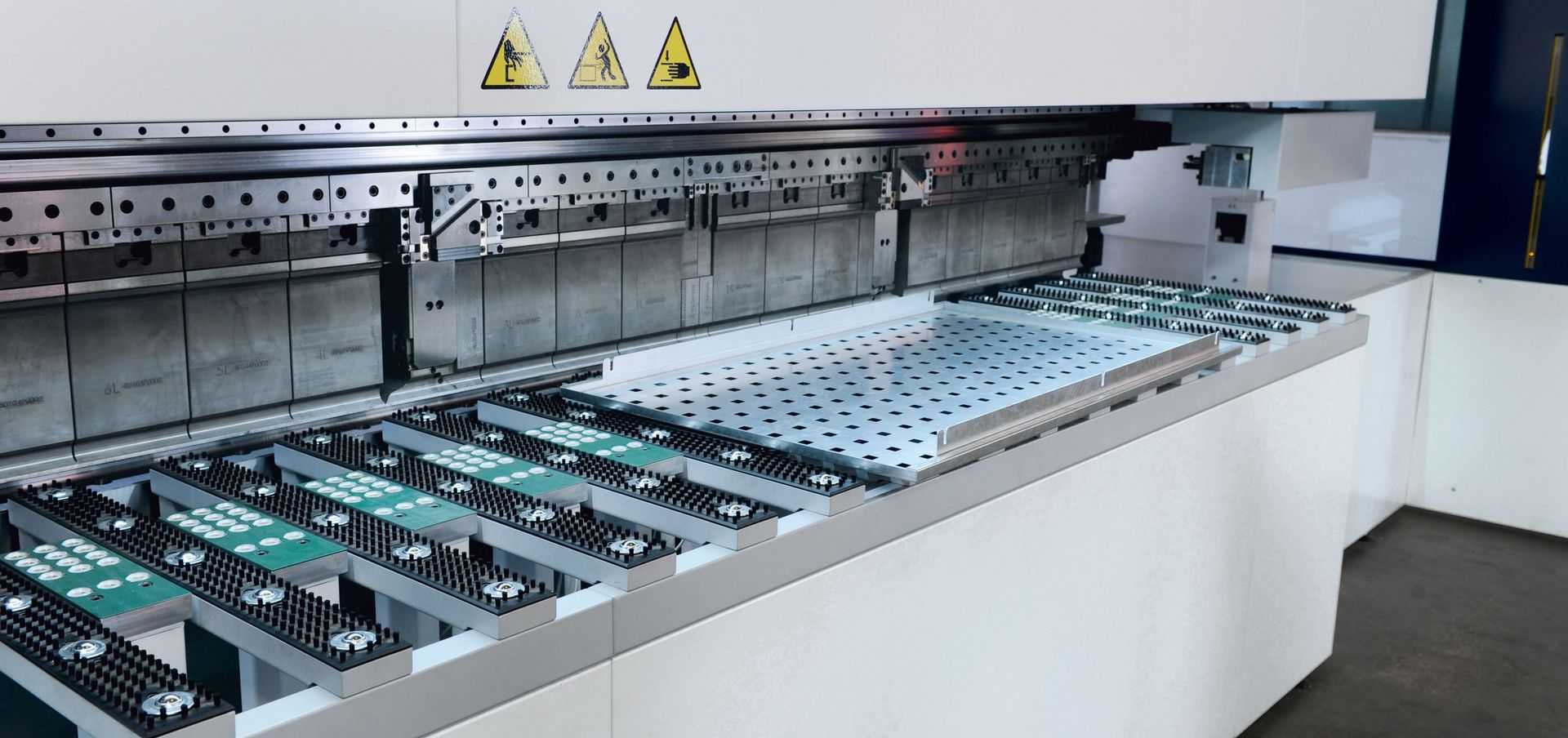

The flexibility of the TruBend Center, even when dealing with small parts, results from the unique machine concept. TRUMPF is the only company in the industry to offer an additional vertical axis at the parts manipulator.

This opens the way to diversity that was previously unachieved. This is because the manipulator can fix the workpieces at differing positions. In this way parts with negative bends and very narrow profiles can be manufactured. Even when using standard tools, the TruBend Center offers a large variety of sizes and shapes: extremely short side lengths, deep boxes, small profiles and, over and above this, parts with formed sections, recesses and widely diverse radii. Also the concept for machining perforated sheets is well thought out. Suction cups or optional magnetic clamps, built for flexible positioning, hold the sheet firmly in place.

“The panel bending technology in the TruBend Center 5030 offers us new options,” Bickel confirms. “This has also inspired our collaborative partners to go into modern design.” Many sheet metal components are now graced with a crowned front surface. A part taken from a housing demonstrates how well panel bending technology and die bending can complement each other. The TruBend Center first performs the radius bending operation to create the crowned face. After that, a press brake shapes the legs exactly to specifications.

The route leading Bickel Blechtechnik to the TruBend Center started a long way back. For a good five years, the company’s owner had panel bending on his mind. Virtually all the offers available on the market were examined by him and his manufacturing manager, Roland Jenz. But it was only when TRUMPF acquired Codatto that the package came together. Bickel: “We had long been more than convinced by the flexibility of the machines from the Italian town of Lonigo. Since TRUMPF has taken over the products and the technology, we are now sure of the service support that we need.” Even after a malfunction, no machine can stay down very long at Bickel Blechtechnik. The team itself handles maintenance and repairs and much appreciates the TRUMPF spare parts service and the manufacturer’s expert hotline.

Bickel GmbH Metallbau Blechtechnik, Oberderdingen, Germany. Founded in 1983, 40 employees. www.bickel-blechtechnik.de

Using the latest machinery Bickel manufactures high-quality parts from steel, stainless steel and aluminum for a wide range of sectors, including mechanical engineering, apparatus engineering and control cabinet engineering. The focus lays on complex assemplies.

TruBend Center 5030 and TC 500 R-13