What are the challenges involved in chipping Inconel?

Inconel® is inherently very firm. Tool costs are high because cutting tools wear out quickly when milling Inconel®. In some cases, this has a knock-on effect on quality, because the milling machine may not detect a worn cutting tool. Part manufacturers also waste considerable quantities of material. Components made from Inconel® – such as turbine blades and gas compressor impellers – tend to be complex. Milling machine operators often have to remove up to 80 percent of the raw material to create the required shape. With Inconel® retailing at around 100 euros per kilogram, this incurs significant costs.

What advantages does 3D printing offer when it comes to Inconel processing?

By using 3D printing, Inconel parts can be produced faster, cheaper and at higher levels of quality. Unlike material removal methods such as milling and turning, a 3D printer does not waste material, because it only uses the amount of powder that actually needs to be melted to create the part. Virtually no manual post-processing is required, which significantly reduces tool costs. What’s more, 3D printing achieves higher levels of quality by making it easier to create complex geometries. For example, it greatly simplifies the process of fabricating internal cooling channels that increase a component’s performance and service life.

When is Inconel used?

Whenever it’s getting hot. The material can withstand temperatures of up to 700 degrees Celsius without deforming. Therefore it is used in applications such as gas turbines, combustion engines and heating systems

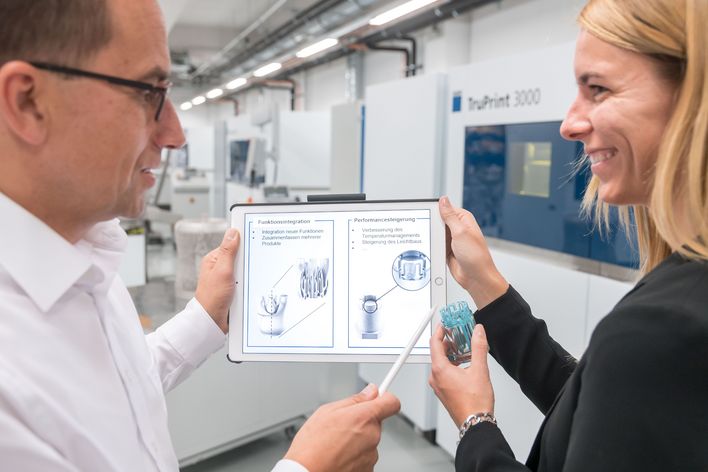

Are there any examples of TRUMPF improving the processing of Inconel using 3D printing?

Yes, recently we have printed a gas compressor impeller made from Inconel. It is used to operate postal delivery drones and model aircraft as well as in small-scale turbines. Conventional manufacturing methods are time-consuming and resource-intensive. It takes a total of eight days to mill the part from a block of Inconel, including post-processing, and the tool costs are high. Our 3D printer TruPrint 3000 can build three impellers simultaneously on the printer platform. The total time required to produce each piece is just four days, including post-processing. The milling machine is only required for post-processing, which reduces material loss to less than 20 percent. 3D measurements have shown that the printed gas compressor offers the same level of quality as the original.