BIGSTEEL emerged out of a profit center that was originally a metalworking company’s sheet metal unit. Oliver Frank, 33 years old at the time, recognized its potential. He proposed that it could manufacture products of its own and then jointly founded BIGSTEEL AG in 2011 with his former boss and current partner. It was the right decision. The company grew so fast that it wasn’t long before the plant was bursting at the seams. That is when Frank clinched another marquee deal, taking over a company that specializes in vehicle interiors to branch out the firm’s portfolio.

Off the farm and onto the shop floor

Even if the name suggests otherwise, Frank never expected BIGSTEEL AG from Hergiswil in the Swiss canton of Nidwalden to become as a big as it is now. These days, he and his workforce supply sheet metal parts to customers throughout Switzerland.

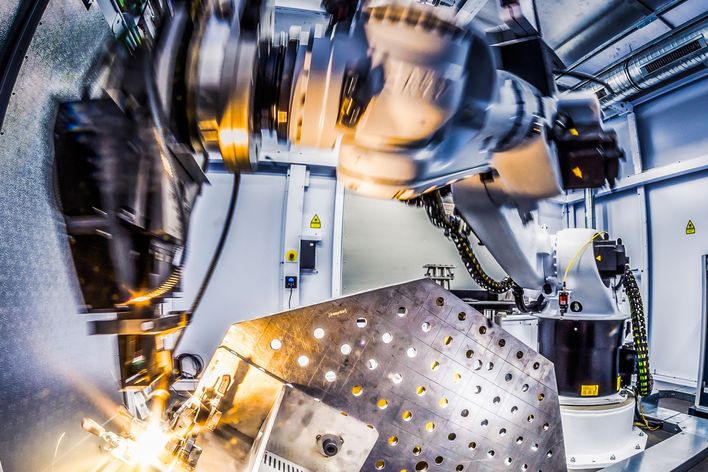

Anything goes, from small parts and custom builds to entire facades. “One project that I am particularly proud of is the University of Lucerne’s facade. We’re the ones behind the design and striking appearance,” says Frank. One of the company’s specialties is machining large components measuring up to two-by-six meters. The entrepreneur now has 35 permanent employees on board. Frank also works with another company to “borrow” employees as and when needed. This is creative and very helpful indeed. “We even have two former employees who now work on their parents’ farm, but come back to operate our machines again at peak times,” says Frank. And these peak times come around often because the company is as agile as its customers. Orders and jobs can be planned and handled very quickly, as BIGSTEEL is known for its fast delivery. To this end, the company always works in two shifts and sometimes in three shifts or with a ghost shift where the machines run without human operators.

On course for expansion

There is no rest for the machines, ever. “We used to have machines from other manufacturers. However, we soon switched to and stuck with TRUMPF products. One important factor in this decision was definitely the service.” Frank knows he can count on TRUMPF Schweiz AG to be well organized and quick to respond. Or as he puts it, “Service is a company’s calling card. And TRUMPF’s is particularly attractive.” In addition to the first expansion shortly after the company was founded, BIGSTEEL also acquired a company in Egerkingen - about 60 kilometers from Lucerne - in 2016. This company specializes in the production of perforated sheets. Frank found some pretty ancient machines on site, which he has now also replaced with TRUMPF products: “I completely overhauled the company and its machinery. We want to offer our customers an end-to-end package and leverage synergies to do this.” Asked why he decided to expand even further, Frank says, “sooner or later you get to that point, you’re either satisfied or you keep pushing. As it happens, I always keep pushing for more.”