TruLaser Series 5000 laser cutting machines offer an impressive 12 kilowatts of laser power with the TruDisk 12001 // Intelligent systems enable more reliable processes and highly productive flame and fusion cutting

TRUMPF presents the new TruLaser Series 5000 with intelligent assistance systems

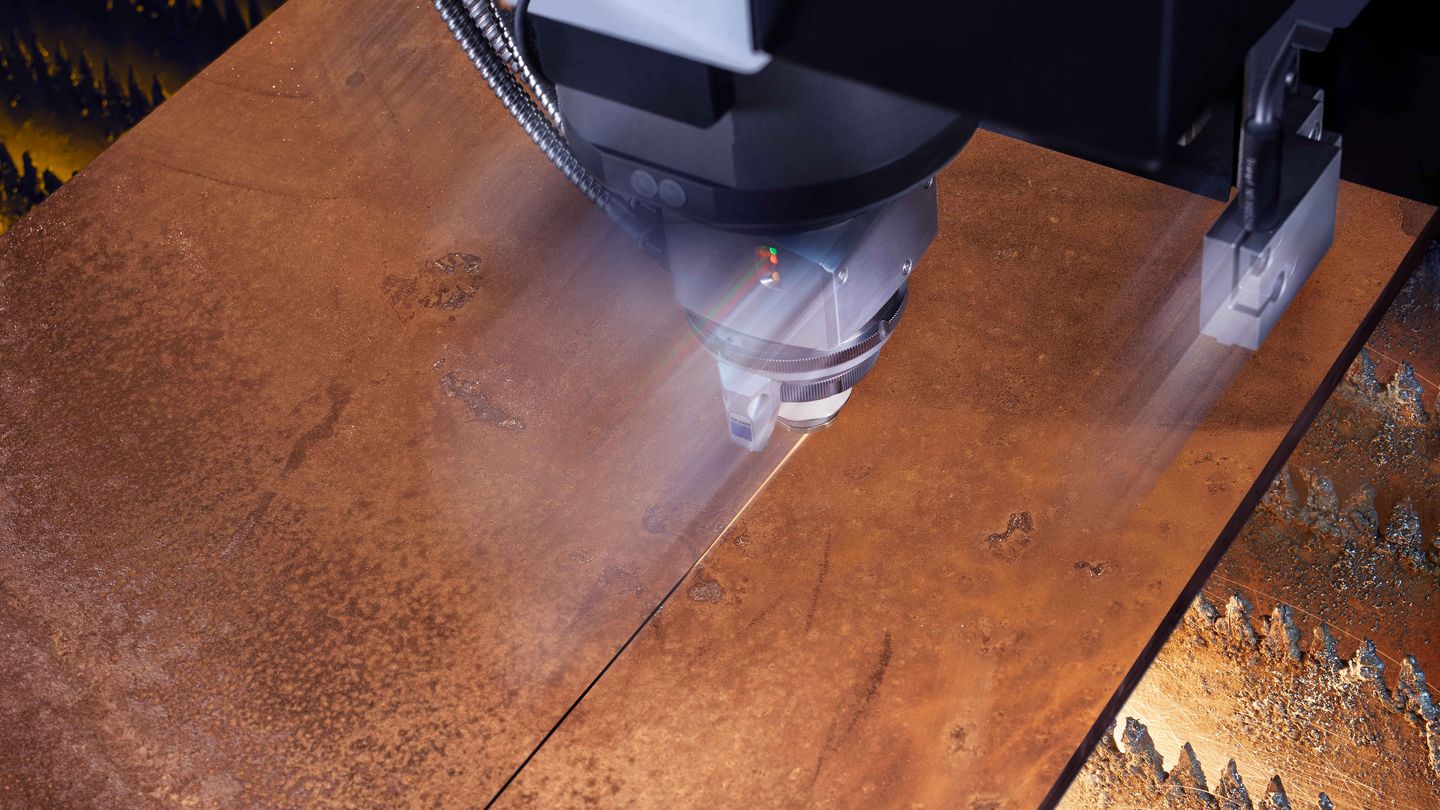

Ditzingen, October 26, 2020 – Machine tool specialist TRUMPF has equipped its latest TruLaser Series 5000 laser cutting machines with a TruDisk 12001 disk laser with 12 kilowatts of laser power. The new machines also come with intelligent assistance systems that increase feed rates for medium and high sheet thicknesses by up to 50 percent compared to conventional laser machines with a ten-kilowatt laser. Higher feed rates mean higher throughput, with these new machines handling up to 20 percent more sheets an hour. The latest TruLaser Series 5000 machines come with tried-and-tested features such as Active Speed Control and BrightLine Fiber, which lead to more reliable processes and higher-quality parts in both flame and fusion cutting.

Machine productivity makes the difference

Hendrik Meidert, product manager for the TRUMPF TruLaser Series 5000, explains what makes these new machines so special: “Boosting feed rates by increasing laser power saves time in the cutting process, but that’s only part of the equation. For us, it’s equally important to ensure that we increase sheet throughput in order to improve the machine’s overall productivity. The key here is to reduce non-productive time or eliminate it altogether.”

It is not uncommon for problems to arise that slow down or stop the production process, especially when cutting thick mild steel. There are plenty of factors that might bring the cutting process to a halt, including dirty sheet surfaces, low-quality materials and variations in thickness between different sheets. This can lead to wasted time and materials. “The higher the laser power and productivity of your machine, the more of an impact it will have when something goes wrong and your machine comes to a standstill. Intelligent assistance systems can prevent those problems from occurring. That’s why we offer functions designed to make dynamic cutting more reliable, especially for high-speed systems such as our TruLaser Series 5000 machines,” says Meidert.

TRUMPF’s intelligent assistance systems have already proved their worth in machines with ten kilowatts of laser power – and all of them are now also available for TruLaser Series 5000 machines with 12 kilowatts of laser power:

1. Automatic adjustment of the cutting speed

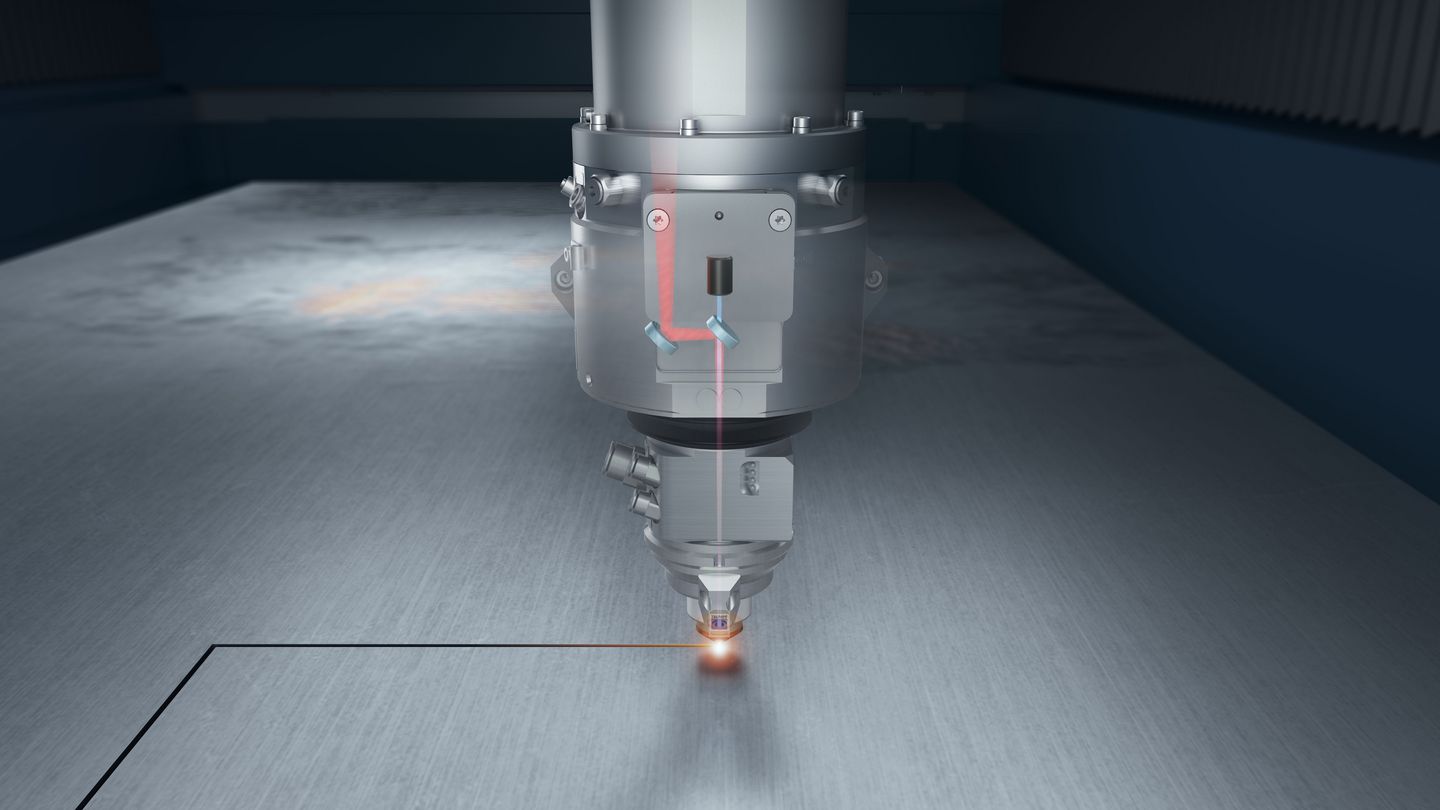

Active Speed Control is the first step on the road to autonomous laser cutting. Machines equipped with this cutting sensor system can automatically control and monitor the cutting process. A camera looks straight through the cutting nozzle right into the kerf in real time, observing the light emitted during the laser cutting process. Changes in the amount of radiation emitted show whether the molten material is being properly ejected from the kerf. Based on this data, Active Speed Control automatically adjusts the feed rate as necessary to ensure that the machine is always cutting at the optimum speed. This balances out any fluctuations in process reliability and reduces the number of rejects in the production process.

2. More parts on each sheet

Another helpful feature for cutting thick material is the CoolLine nozzle, which sprays water onto the workpiece around the laser beam to cool the metal. This prevents heat from building up and negatively affecting the quality of the cut. This cooling function allows users to fit more parts on a single sheet and cut delicate parts more reliably.

3. Cutting lower-quality sheet metal

With the BrightLine fiber function, users can cut mild steel with a large focal diameter. This leads to a wider kerf and improves the quality of the cut edge. The large diameter stabilizes the cutting process, so variations in material quality have hardly any impact on the final result. It also makes it easier to remove parts from the sheet.

4. Automatic nozzle inspection

Smart Nozzle Automation makes life easier for operators by guaranteeing reliable, burr-free cutting. The system switches to the right nozzle and checks it for wear even in fully automated operation. Users can remove the nozzle changer from the machine and set it up even during cutting. This helps minimize non-productive time.

The smart way to increase throughput

All in all, the TruLaser Series 5000 with 12 kilowatts of laser power sets new standards of productivity, efficiency and reliability. It is the perfect choice for customers who need a reliable process for cutting medium to thick sheets and prefer to take a smart approach to increasing throughput. The TruDisk 12001 is available for the TruLaser 5030 fiber, the TruLaser 5040 fiber and the TruLaser 5060 fiber.

Digital photographs in print-ready resolution are available to illustrate this press release. They may only be used for editorial purposes. Use is free of charge when credit is given as “Photo: TRUMPF”. Graphic editing – except for cropping the main subject – is prohibited. Additional photos can be accessed at the TRUMPF Media Pool.

Kontaktperson